- ProductBack

Product

- SolutionsBack

- ResourcesBack

A place for visionaries to learn from their peers about getting culture right, NPI, Production, and evaluating new technologies

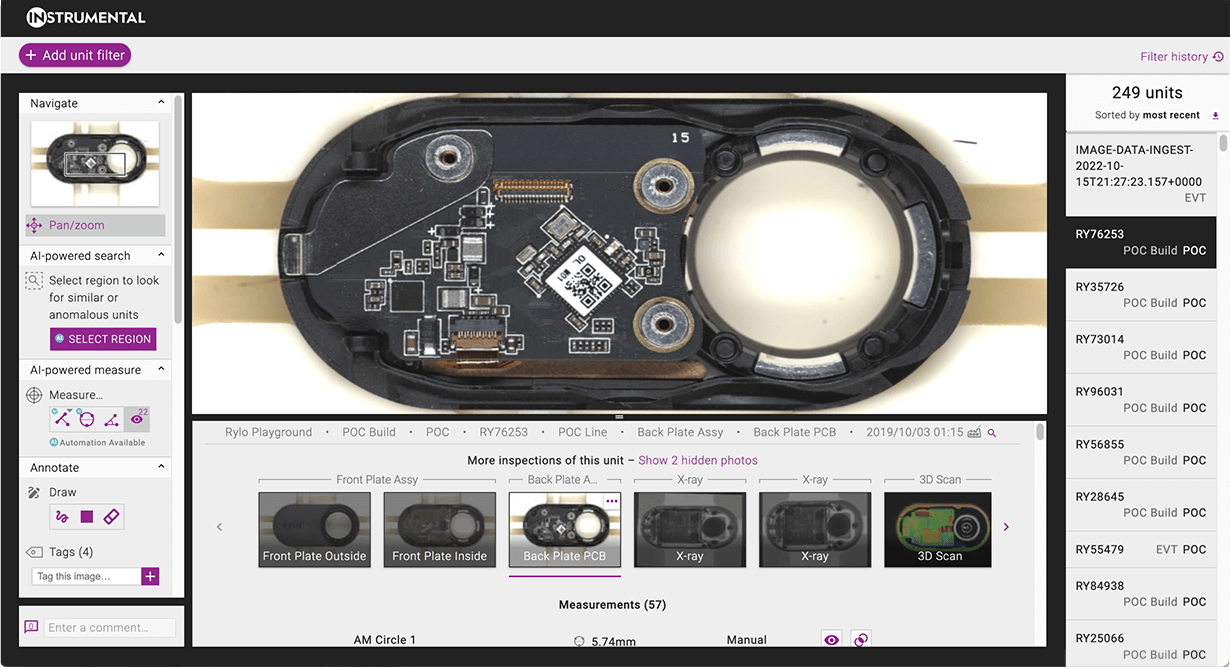

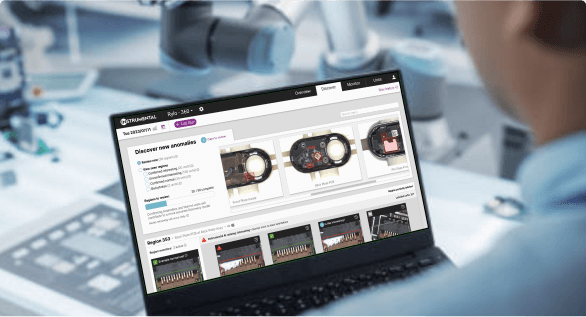

See how companies are using Instrumental

- CompanyBack

- Log in SPEAK TO AN EXPERT

- Search