Released on Aug 24, 2021, the Nest Doorbell (Battery) was redesigned from the ground up with a sleeker, simpler design and a host of new technologies. On top of all of these improvements, the designers managed to reduce the cost by more than $120 over the first generation. In this episode of Change Notice, ex-Apple engineer Tobias Noonan-Harris and I opened up the doorbell to see how the Google team was able to make those improvements and reduce the cost.

While much of the teardown was done live on my Logitech C930 webcam, the sharpest visuals come from the Instrumental platform, which allows engineers to dive deeper into boards and assemblies. We can even compare similar components across our previous teardowns of the Sonos One and PlayStation 5 controller. This is similar to how Instrumental is used by customers to look for anomalies across millions of units.

To get into the doorbell, I removed 2 long screws from the back before prying into the reveal to unsnap the main housings from each other. This allowed me to butterfly the parts to display the main architecture of the product with the battery and power systems on one side and the board, and the camera and main logic board on the other. Since this product was designed to be used in outdoor environments, we wanted to highlight the environmental sealing of the design. These include the red seals on the two screws, the rubber gasket between the two housings, and the water-resistant chambers for the speaker and mounting mechanism.

Split architecture of the Nest Doorbell (Battery) with the battery and power on one side and main board and sensor modules on the other.

From the Instrumental platform, we zoomed into a few areas of the device including the USB Power flex circuit and the battery. Calling back to the earlier PS5 Controller Teardown, he quickly found image data from that event for a quick compare and contrast discussion. If you’re interested, you can watch that teardown on our Change Notice page. Moving back to the live view, I separated the two halves of the product by disconnecting the USB flex circuit and removed the shield from the back of the camera assembly. While we asked the audience for thoughts on the camera module, I took apart the USB assembly and we theorized on why the screws were so close to some of the power components.

To get a better look at the camera sensor, Tobias zoomed in on the images he had taken previously. Unlike most cell-phone or tablet camera designs, the Nest Doorbell has a removable IR filter and lens system with a rubber gasket protecting the sensor itself from dust. We speculated that this removable lens and filter module could be due to several factors. It could be because the designers wanted to customize the field of view. By using a separate lens module, they could more easily tweak the specifications of the lens before settling on a final configuration. This modular design choice could also allow them to add the powered IR filter choosing when it can be activated in software instead of always being there. Questions from the audience prompted Tobias to show off the fresnel lens over the passive IR sensor which sits just above the camera lens. While we initially thought it might be an ambient light sensor, our sharp-eyed audience suggested that this PIR sensor is more likely used for motion detection. With 8 different lens elements as shown in the image below, the Google team was really trying to maximize the amount of light they could extract from the surroundings.

Camera module and fresnel lensing over the PIR sensor.

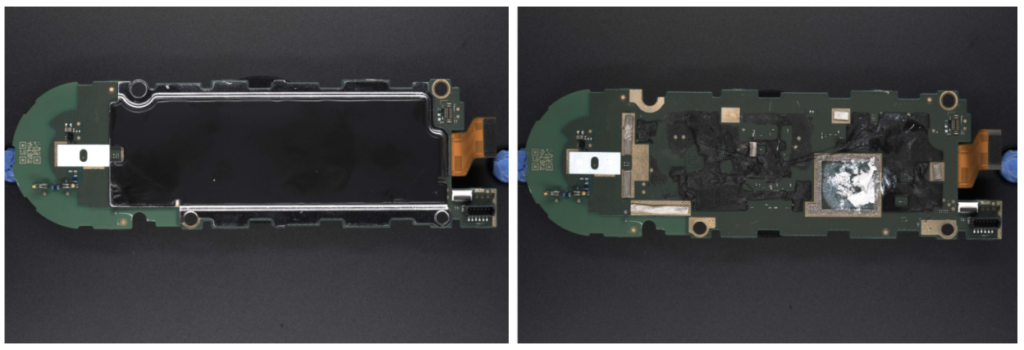

We moved back to the actual teardown to get a better look at the main PCBA from the system. Once I popped out the front button and the plastic light guide, I was able to extract the board. Tobias had some clearer images of it on the platform so we switched back to Instrumental for a close up. Tobias had removed the heat spreader and copper tape above the main shield to reveal some thermal paste directly on an SoC. On the other side, the large metal shield and heat spreader are also connected directly behind the same SoC to distribute the heat away from this main processor. The shield was attached with an aggressive adhesive to keep it in place and multiple conductive adhesives are used to ground it to the board.

Because the heat spreaders and shields are applied using adhesive and thermal paste, it would be pretty difficult to diagnose a problem during development or in production without a manufacturing optimization system like Instrumental. Instead of destructive teardowns like we performed here, it would be simpler to search through data and photos taken in process to verify the critical steps in the assembly process for each anomalous device.

Back of the main board showing heat spreader attached directly to the back of the main processor and attached quite firmly to the PCBA

Front of the Main board showing the heat spreader over the shield can and how it connects to the main processor.

With all of the main elements of the device removed and time running out, we moved to the off the record session to answer more audience questions. One question asked about comparing this generation with the first nest doorbell. Having watched a video from cnet taking that device apart, I noticed a lot of improvements in this new design. Primarily the team reduced the complexity of the system which resulted in a slimmer product with a smaller part count. They also managed to make it easier to assemble and repair at the same time.

There were several calls for us to go further and uncover the components under the shields as well. Unfortunately, we ran out of time but if we get to that in the future, the photos will be added to this teardown. If you’d like access to the photos of this and our other teardowns on the Instrumental platform or want to learn more about how we can help you with manufacturing optimization, contact us at sales@instrumental.com. Watch this space for upcoming teardowns of interesting products!

Chris Li is a former Amazon Product Design Engineer and manager and current teardown lead for Instrumental. He brought multiple generations of the Kindle to market and advised on the first Echo and Fire TV products. He also worked as the VP of Product at a small healthtech startup, PillDrill, which created an award winning medication tracking system.

Related Topics