NVIDIA technology accelerates final stage of L10 assemblies—accelerating critical manufacturing capacity

The ability to manufacture AI servers and racks at scale has become a critical bottleneck in meeting the surge of data center investment. Advanced systems like NVIDIA GB200 and NVIDIA GB300 NVL72 platforms are among the most intricate electronics ever built, each requiring precise assembly, rigorous validation, and meticulous process control.

This complexity slows production throughput, delaying the deployment of the very compute systems that power frontier AI models.

To overcome this challenge, Instrumental and NVIDIA are applying cutting-edge manufacturing AI, trained and deployed on NVIDIA platforms, to accelerate build, debug, and validation cycles. The results speak for themselves: speeding up final system builds by up to 14 days. This demonstrates how AI, accelerated by NVIDIA, is transforming the speed and scale of AI infrastructure manufacturing.

Ingrasys NVIDIA GB300 NVL72

Challenge: Accelerate Server Tray Manufacturing

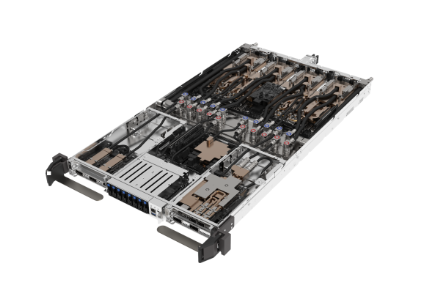

AI servers and racks are among the most complex electronics ever built at scale. Each system is an intricate, largely manual assembly: more than 30 trays per rack, each packed with dense circuit boards and hundreds of mated connectors. High-performance models like the GB200 and GB300 also include liquid cooling systems, adding another layer of complexity.

As data center growth drives surging demand for AI compute, manufacturers face enormous pressure to streamline assembly. Every small gain in throughput translates directly to faster delivery and higher revenue, and is therefore worth pursuing.

The biggest lever for improvement lies in catching assembly errors as early as possible. When issues are fixed on the spot, units can pass testing the first time; improving first-pass yield (FPY), reducing rework costs, and freeing up test capacity. Even small FPY gains have an outsized operational impact, turning delays into deployable systems.

But achieving this is difficult with traditional computer vision tools:

- Variation: Each tray looks slightly different, with unique inspection needs across multiple steps of the build.

- Unknown defects: New failure modes often appear mid-production, long before sufficient labeled data exists.

- Multiple SKUs: Many product families ship in several configurations, each requiring its own detailed visual inspection plan.

Conventional automated inspection systems struggle to adapt to this level of variation and complexity, which is why most manufacturers still rely heavily on manual inspection.

At the same time, new manufacturing sites are coming online worldwide, including in the United States, to boost capacity. Yet quality control often varies between locations due to differences in tools, processes, and operator experience. The ideal state is a unified quality standard; one where every discovery or improvement at a single site is instantly shared and adopted across all factories building the same product.

Solution: Synchronized Visual AI

Instrumental’s manufacturing AI and data platform gives engineers the tools to boost throughput and quality in Level-10 (L10) tray manufacturing.

Technology

By capturing high-resolution images of every unit across multiple assembly stages, Instrumental provides 100% visual traceability and automatically detects defects, deploys updated models, and surfaces actionable insights directly on the line.

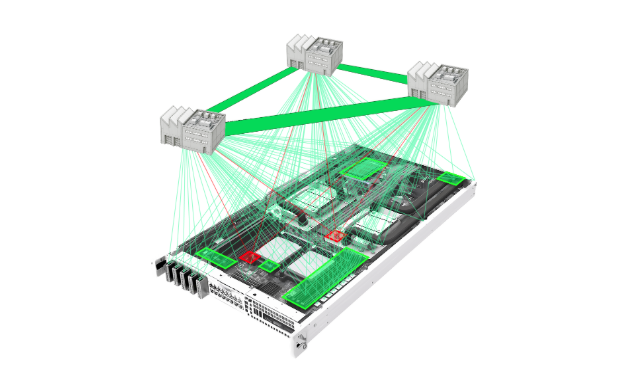

Unlike traditional machine vision systems that rely on static, rule-based models, Instrumental’s approach pushes modern AI hardware and software to their limits. Powered by NVIDIA Metropolis, its proprietary vision models continuously learn from every new unit, using self- and semi-supervised learning to distinguish normal variation from true anomalies. The result: the system can flag both known and never-before-seen issues without waiting for retraining or labeled data.

At the edge, NVIDIA AI infrastructure on the factory floor analyzes anywhere between 30 to 250 inspections in just a few seconds , delivering instant feedback to operators—something CPU-based vision systems simply can’t achieve.

But the major breakthrough from these deployments is that AI models can be synchronized across SKUs, lines, and factories, creating a unified global standard of quality and “Day 1” readiness for new sites. But this isn’t limited only to NVIDIA – partners building on NVIDIA MGX reference architectures can now also use models built with NVIDIA data to accelerate their own production ramp.

Factories, located across the globe, are now connected, sharing key training data sets. Allowing existing factories to learn from each other, and enabling new ones to be up and running on day 1, accelerating factory ramp up.

Across NVIDIA’s global manufacturing network, Instrumental proactively identifies assembly errors before they cause downstream test failures. Cameras mounted above manual stations and integrated into automated fixtures capture every key step of the build. Deployment is fast—typically only a few weeks from order to live defect interception—and value begins immediately.

Common defects intercepted by Instrumental’s visual AI include:

- Connector issues: latches not fully engaged, plugs not fully mated, or bent pins

- Missing or mismatched parts: incorrect components for a given SKU

- Thermal management defects: missing or damaged thermal interface materials, misaligned leak sensors

- Wire and cable routing errors: mis-routed or unsecured harnesses

When a defect is detected, the unit is fixed immediately on the line—preventing failed tests, rework, and wasted hours. Every image and test result is automatically logged, creating a complete visual and functional record of each unit. Remote teams can then collaborate in real time on failure analysis, root-cause investigations, and continuous process improvement.

Real-time pass/fail feedback lets operators fix issues on the spot, preventing expensive rework and keeping production moving.

Each tray that passes functional testing on the first attempt eliminates additional test cycles, rework labor, and lost capacity. The result is faster throughput, lower costs, and shorter delivery times.

Instrumental is collaborating with NVIDIA to make its GB200 NVL72 and GB300 training sets available to MGX System Partners. In addition, NVIDIA plans to enable MGX partners to contribute their own findings back to those models, allowing all contributing partners to gain efficiencies together.

“NVIDIA has led the industry by open-sourcing its revolutionary compute tray and rack designs with the Open Compute Project and providing NVIDIA MGX System Partners with a functional test suite. With this new initiative, NVIDIA will expand on that leadership by providing its partners with a pre-trained ‘visual test suite’ that streamlines their manufacturing,” says Anna-Katrina Shedletsky, CEO and cofounder of Instrumental.

Author

Related Topics