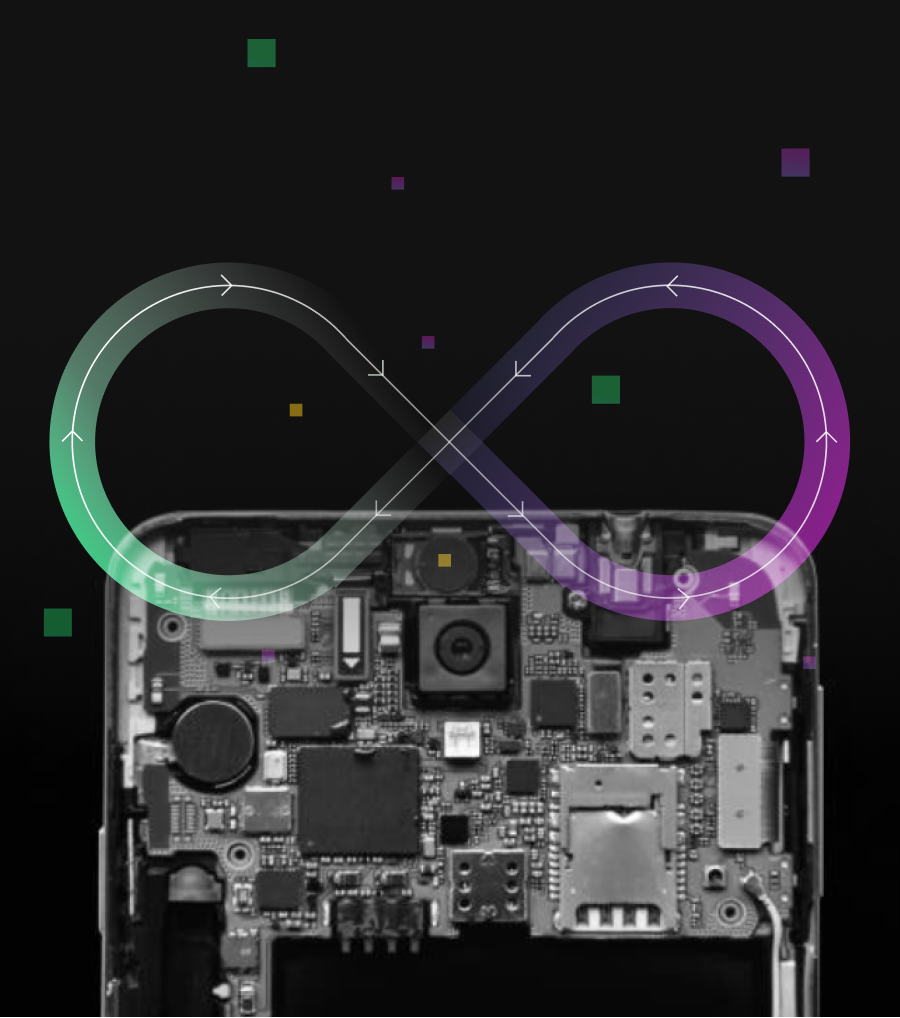

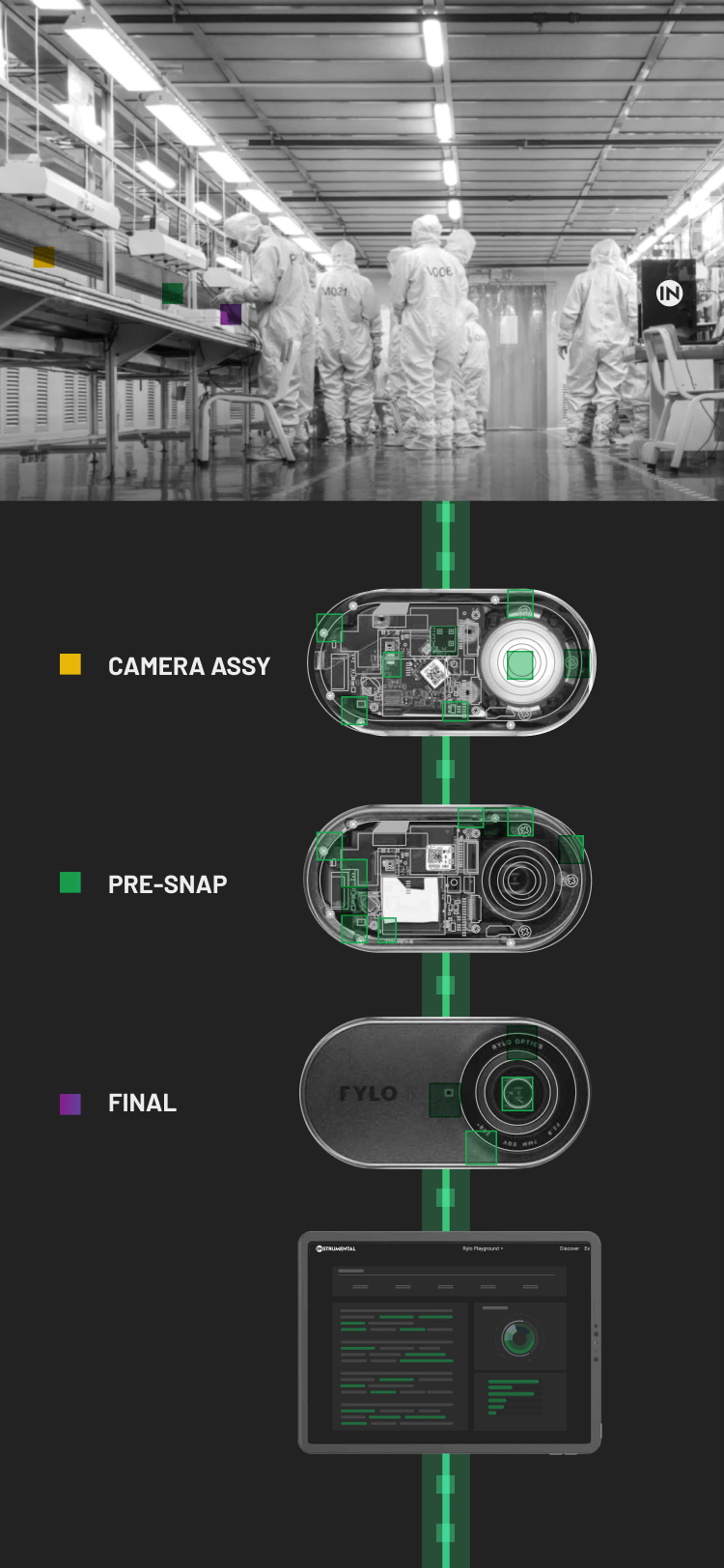

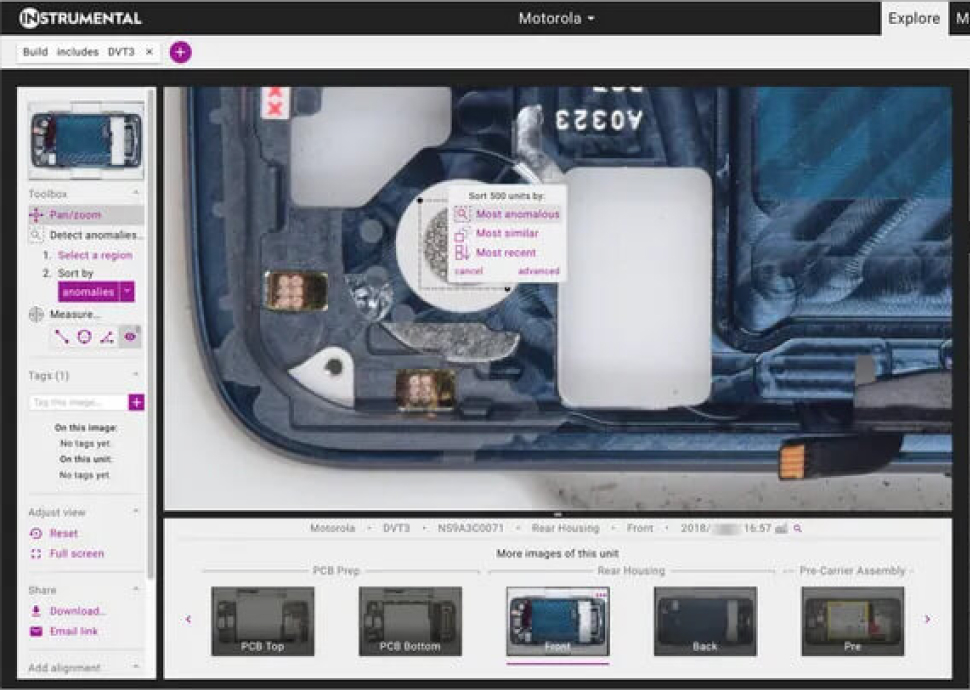

Pinpoint root cause in minutes

Instrumental automatically finds correlations between functional test results and visual anomalies, so getting to root cause takes minutes, not weeks.

Make decisions faster with real-time data and insights

Connect with your factory floor in real-time, from wherever you are. Eliminate last-minute travel, painful multi-day miscommunications, and long nighttime meetings from your NPI programs.

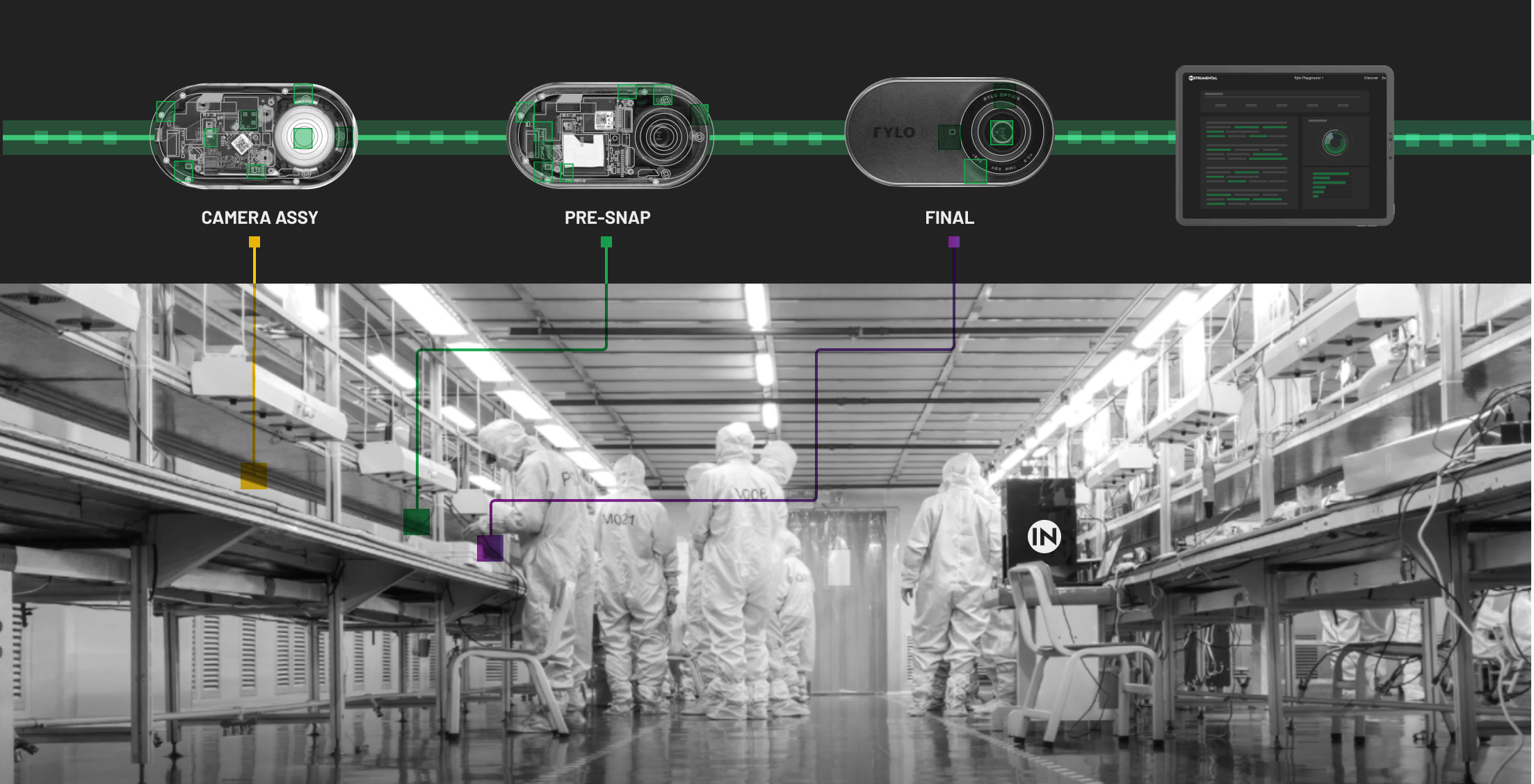

Experience simple setup built to solve problems, not create them

We know you don’t have the bandwidth for complex implementations. That’s why installation takes less than 30 minutes, and time savings start on Day 1.

Learn about the Instrumental platform