Break down your product data silos for faster failure analysis

Key Takeaways

- Instrumental pulls all of your product data (photos, parametric test station data, measurements, custom datasets) into a secure cloud.

- Your entire engineering and manufacturing teams can see build and defect data in real time

- Get super-simple filters and views that help connect the dots between your data for lightning-fast root cause analysis

Start with correlation. Get to causation faster.

You’re probably already collecting some combination of product data today. It may come from off-the-shelf systems or internally engineered data sources, such as:

- Parametric data from functional tests like RF performance, speaker and mic tests, air leak test, etc.

- Geometric measurements for critical components

- End-of-line inspection results from AOI or human inspectors

- X-rays or thermal images

- Other custom parametric data

But there’s a problem. That data is typically in silos, and what you can access is often incomplete and only accessible from within the facility where it’s collected. In the best of times, gathering and analyzing data to diagnose, analyze, and solve manufacturing issues was a painstaking and time-consuming process. Now, without travel or even face-to-face time with your local team, it can feel impossible.

Experienced product engineers know that most failures aren’t black and white. Often issues cause partial or intermittent functional failures that are difficult to replicate. Pass-fail data isn’t usually enough to serve an engineering purpose, as the difference between a marginal failure and a complete failure can provide valuable clues. Defects can be irregular, such as those common in glue processes, or may be the result of up-stream supply chain issues where there is little data and diagnostics rely on hearsay or email communication.

This means that connecting downstream issues to their root cause is rarely easy, often requiring significant forensics across multiple experiments and many hours. Sometimes, the necessary data does exist but is hard to get to, siloed in a supplier’s MES, on the test stations themselves, or across different difficult-to-use systems. It can also be incomplete, which is why many teams send engineers to the factory: to be close to the units and the data. And without a common source of truth between brand and factory, sensitive data can often end up on less secure channels like email.

These types of issues can add weeks of schedule slip, cost tens to hundreds of thousands of dollars in engineering time and travel, and — in the most intractable cases — cause entire program cancellations.

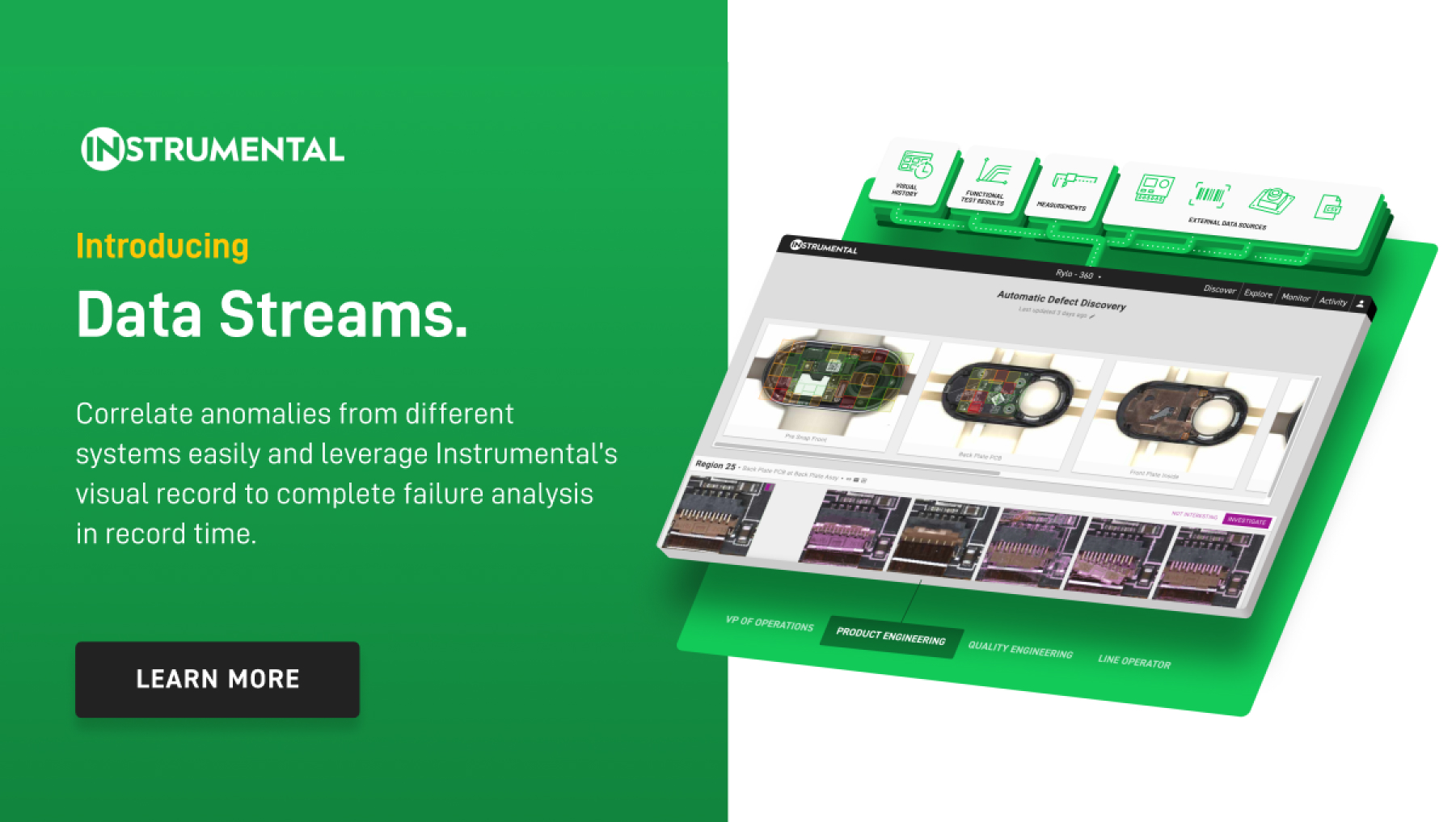

All of this is why we’re excited to introduce Data Streams, which enables Instrumental’s platform to ingest product data from across your existing tests and inspection systems, and bring it together in a secure hosted cloud for easy access from anywhere.

Simplify failure analysis workflows to find correlated inputs and outputs

Data Streams makes it easy to quickly connect the dots between downstream signals like test failures and their upstream causes. Because Instrumental already collects complete visual histories of every unit off your lines in development and production, engineers can skip straight from test results to root cause in minutes instead of months.

Instrumental can now ingest almost any type of product data, organize it by unit, and visualize it alongside that unit’s visual history in our app, all in real time. This means the right data gets in front of the right team members, when they need it most.

Filter and sort by test results with handy side-by-side visual histories of each unit.

From there, they can sort and filter across data sets and narrow down possible causes in a matter of minutes. Data Streams enables product engineers to:

- Complete root cause analysis of failed units faster

- Analyze data to find trends that correlate with failures or visual defects

- View the complete production history of a unit in one place

- Quickly assess the cause of field failures or returns when integrated with return center data

- Determine Pass / Fail limits for a particular test station based on the distribution of results

Instrumental Data Streams is already helping our customers solve problems faster, including some they had previously given up on. When you reduce the time it takes your team to discover, diagnose, and fix an issue, and eliminate time wasted in transit, you make it possible for them to hit higher yields on shorter schedules.

Does your 2021 remote manufacturing plan include a remote data strategy?

You’ve probably already developed a new pandemic operating playbook that includes protocols for disinfecting and distancing, Return to Work guidelines, and new standards for travel, all focused on keeping team members as safe as possible.

A large percentage of travel in manufacturing happens because individuals can’t get the data they need to do their jobs effectively any other way. With Instrumental’s cloud-platform, the data your engineers and operations teams need comes to them, so managing builds remotely is even easier than it is in person. Instrumental customers are already turning their data accessibility into an asset for the New Normal.

If you haven’t already considered how your product engineering tech stack can help reduce the need for in-person travel without sacrificing speed, we’re here to help!

Related Topics