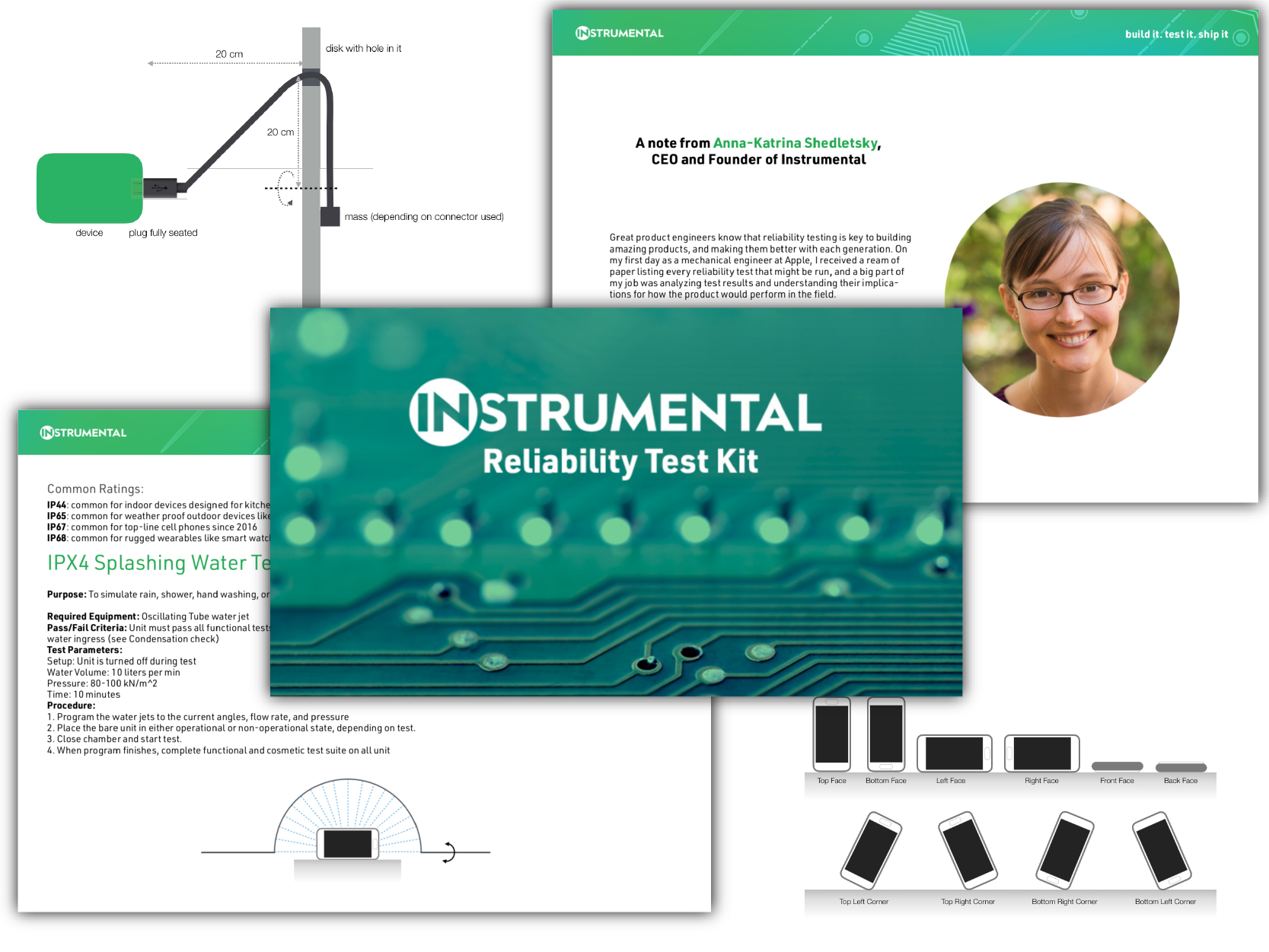

Download the best guide to reliability testing

Get 30+ pages of testing best practices, methods, diagrams, and more!

Clear methodologies, diagrams, tips, and more that will help you build better by surfacing your product’s weaknesses.

Get 30+ pages of testing best practices, methods, diagrams, and more!

Reliability testing enables engineers to catch issues that may degrade a product’s field performance, and characterize risk under different failure conditions. Reliability tests also catch issues that can’t be found through other methods, such as discovering that you picked the wrong plating on an electrical contact. A unit may work fine in the factory, but may fail once exposed to the harsher environment of the real world. Something as common as sweat could cause plating corrosion and would only be discovered through reliability testing. Reliability tests provide unique insight into product failings and allow teams to build better.

This kit is the result of combined decades of experience with top manufacturers and deep familiarity with regulatory testing requirements, and is intended as a comprehensive guide to reliability testing. Our team of mechanical engineers and manufacturing experts has included detailed test definitions, setup parameters, and instructions for a wide range of reliability tests, demonstrating best practices for some of the most common testing scenarios.

The documentation includes a thorough set of environmental, mechanical, and coating tests. We’ll walk you through how to conduct tests that cover, among other areas:

While this test plan could easily be factory-ready, it’s very important that you customize your plan to the product you are building. Instrumental’s kit provides frameworks for building well-designed tests. It also discusses how to extend or customize tests for your product in addition to the level of of specificity you’ll need to get actionable results.

Our advice: Take a look at the tests, then decide if and how your particular product can benefit from each one. Determine whether you need to make modifications to make the tests more suitable for your product — or which tests might be missing. Review our post on how to plan for success when developing your reliability testing process.

It’s important to set up these tests on a schedule that allows for remedial action, including tooling modifications and a buffer zone for big issues. Think ahead to the results you’re expecting, and to what you’ll be able to do in the best- and worst-case scenarios. We wrote more about how to conduct a solid reliability testing process here.

If you already have a reliability test plan, our kit is still useful. Take a look at our testing guidelines and see if your company adheres to the best practices we’ve outlined, or if there might be a relevant test scenario you haven’t considered. If you have feedback, feel free to get in touch!

Instrumental captures images on the assembly line and leverages AI to detect defects during development and production.

Learn more