Failure analysis is hard for manufacturers – whether remote or on the line. It is often difficult and takes too long to get the data you need to identify and make the right corrective action – and more difficult still to monitor whether your corrective action had any further downstream impacts.

This ultimately pulls focus from a team already spread thin by an aggressive build schedule. And every moment spent on data collection and analysis takes away time and focus that would be better spent accelerating product maturity, time-to-market, and building better products.

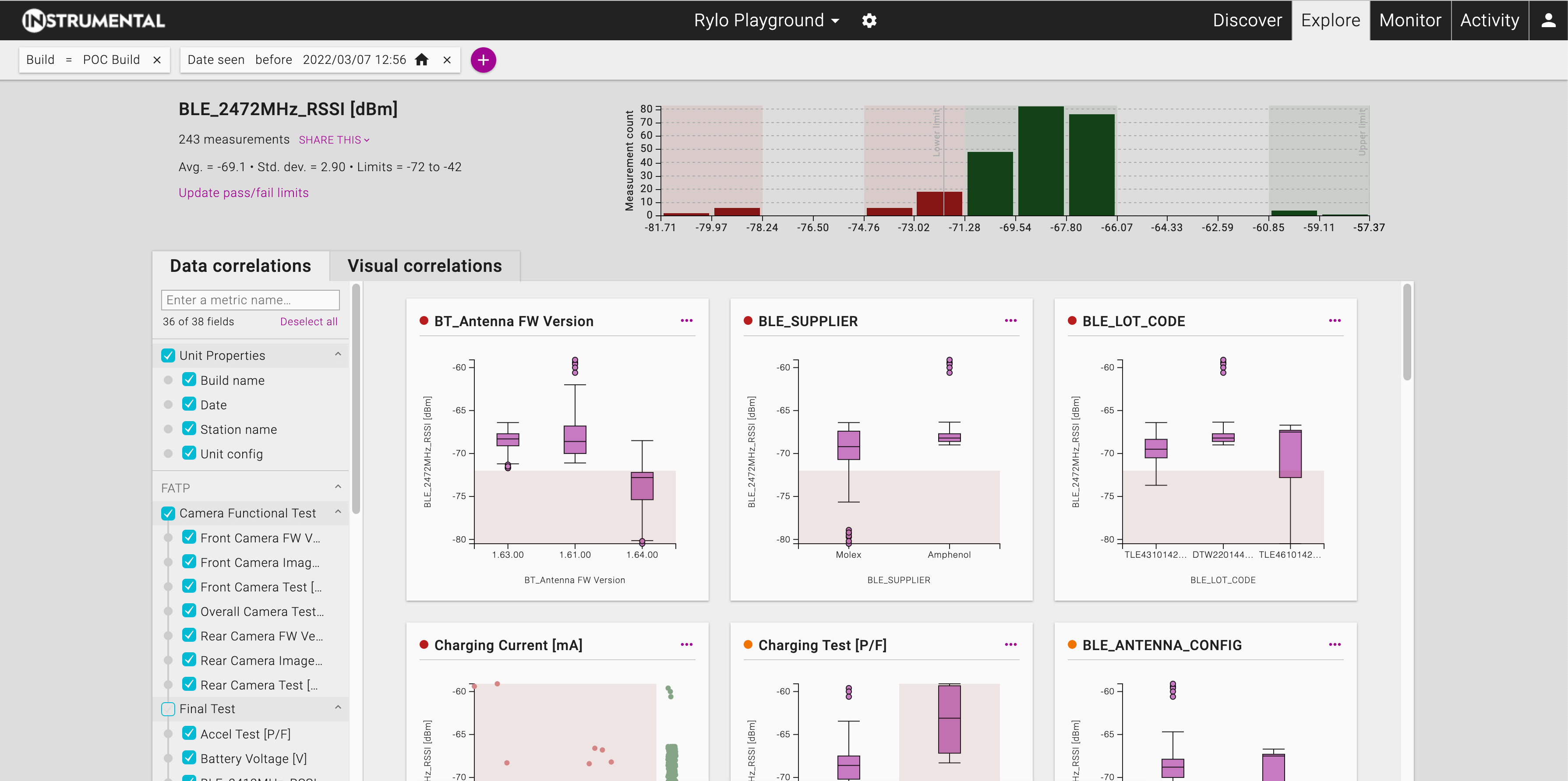

Announcing Instrumental Correlations – a data-centric approach to failure analysis that helps manufacturing teams solve bigger problems faster. Instrumental Correlations helps manufacturing teams quickly identify correlations with an AI-ranked list of the most actionable relationships in your product data that can cut down the time needed to identify root cause and implement corrective actions.

Types of data you can can correlate:

- Functional tests

- Measurements (from other equipment)

- Supplier data (vendors, lot codes)

- Image data (i.e. humidity, temperature, operator)

- Field data (customer usage, returns)

Spend less time collecting data, and more time engineering solutions

It all starts with a ‘hint’ that something is not right on your line – maybe you observe sub-optimal yields or increase in returns, or other waste during manufacturing and cannot easily identify what the problem is. Maybe a cohort of units is showing signs of connectivity performance loss in DVT because of an issue which was never found (or solved) in EVT. The problem is that the data needed to get to the bottom of an issue is never where you need it, when you need it.

Each data point becomes an isolated piece of hay loosely collected in separate piles labeled supplier, tests, vision system, or parametric data – and they don’t mix. You go from being an engineer to a forensic farmer – spending more time on harvesting data than innovating design – and there’s never a guarantee you’ll ever find the needle at the bottom of a haystack of failures. With Instrumental Correlations, engineers now have a magnet for root causes – no sifting necessary.

Get to root cause faster without waiting for your CM

We hear from our peers in the industry how much time and effort it takes just to get information from your own factory. You may play an unending ‘waiting game’ with your CM just to get an email with a spreadsheet attached – and there’s no guarantee it’s what you need or in the format you need. And each back-and-forth gets extended by time-zone conflicts and lost-in-translation mishaps.

In a recent 2022 State of Mass Production Survey, we found that 13% of an engineer’s time is spent on low-value pre-processing of data and not on engineering solutions. This is because once the data has been collected, it still needs to be reformatted in order to run a proper analysis – which can take hours, days, or even weeks. Once the manual cleanup has been completed, the real work begins: building relationships between the data to surface correlations that identify the root cause of the problem.

Instrumental eliminates the waiting game and gives you real-time access to your data and to the analysis.

What can Instrumental Correlations do for my line – specifically?

Got bad antennas? Hand solder issues? Improper conformal coat masking? Instrumental Correlations will rank highly actionable relationships to product properties (like build, config, fixture ID, vendors, etc) and other functional tests themselves. This immediately unblocks your team by helping them find an actionable next step in the failure analysis process.

This is a completely new & unique way to solve your hardest problems and ship on time using a combination of images and test data. If you’ve struggled with aggregating data, finding the resources to do a proper analysis, and identifying invisible or other intractable problems – Instrumental can help.

Can I get started today? Yes, you can.

You can start using Data Correlations with either images using Image Streams or data using Data Streams. Our Image Streams product has AI to discover new anomalies. Our Data Streams product has AI to discover relationships and correlations in functional test data. The real magic happens when you combine them both. Instrumental’s technology is the only one in the world that enables mixed-type correlations between your test data and your images – which means our AI can automatically identify potential root causes for your test failures.

Instrumental unifies your product data to deliver the information you need, when and where you need it, so you can find and fix problems fast. Get up and running quickly with existing test data – no additional hardware required and no setup needed. You don’t even have to touch the line.

Effortlessly leverage your existing data by using Instrumental AI to identify correlations in everything you’re collecting, from functional tests to measurements. Get set up in days and results in minutes with AI that automatically finds and ranks every defect, speeds up failure analysis, and keeps your builds on track.

Schedule a demo here to see if Instrumental can help accelerate your next program.

Related Topics