As the world begins to return to normal, brands and manufacturers will have to figure out how to manage this changing environment several months ahead of time. With products being finalized in the coming weeks and months, decisions need to be made now to hit planned summer and holiday launches at the right scale and to load the right channels. Where you can, exert tighter oversight of things you can control and determine how to be flexible enough to navigate the challenges from the aftershocks of the pandemic.

Follow these tips to de-risk your production ramp in 2021.

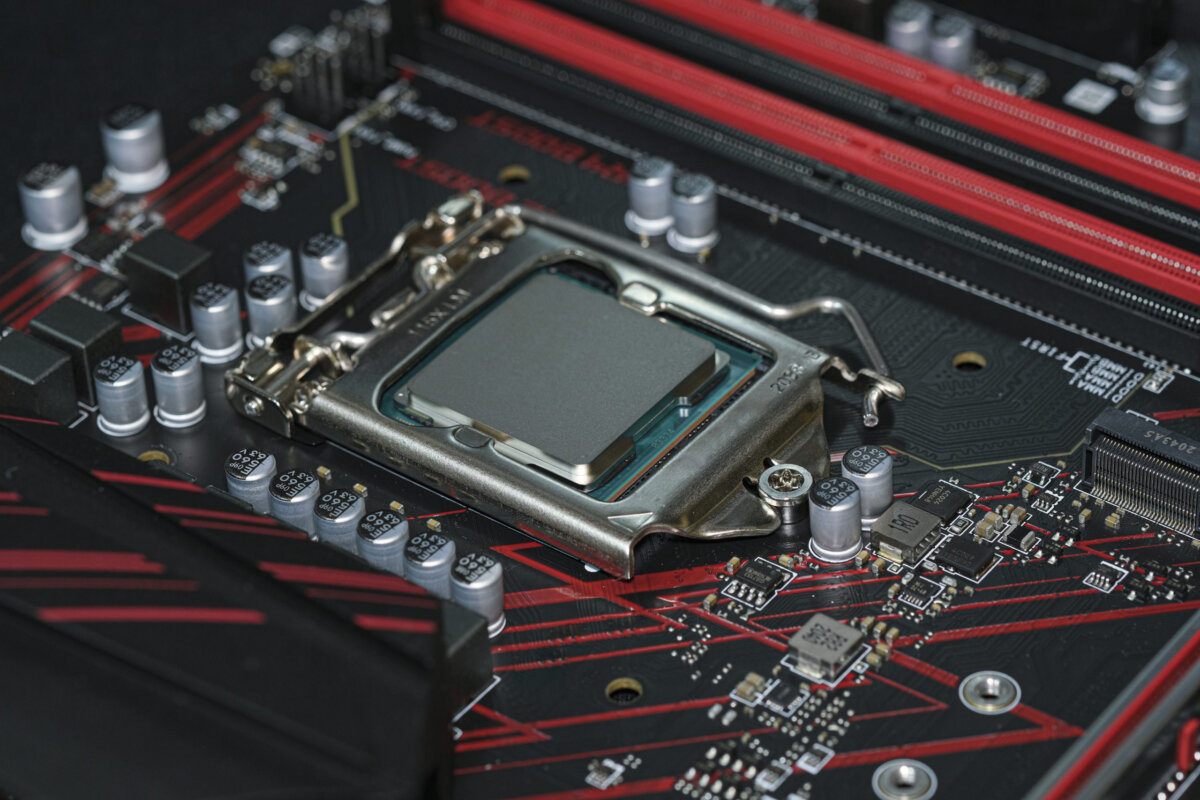

1. Get those chips

The great semiconductor shortage of 2021 has left many companies in a terrible bind having to scramble to find enough chips to complete products. Companies like GM, Ford, and Tesla are being forced to limit the number of cars and trucks they make missing out on billions in potential sales and idling production lines. Consumer and industrial product manufacturers are not faring much better. Sony has already said that shipments for their PS5 which was released in 2020, may not be running at full capacity until 2022! With many suppliers booked solid, lead times for components can be up to or more than 26 weeks.

If your teams haven’t already placed orders for the fall and beyond, you should carefully review your ramp and sales plans and determine how much supply you need to order as soon as possible. Unlike previous years where you could push off the decision to purchase materials once you had completed DVT, this year consider shifting the risk to buying more raw materials earlier to avoid having to shut down your lines in the middle of PVT and ramp. If you have alternate suppliers for certain chips or components, you may also need to spend time validating different configurations in parallel to have as many mix and match options as possible.

2. Bring up new lines strategically

Depending on your volumes, you might need to qualify new lines to hit your ramp numbers. If you are able to hit your design milestones on time or early and can lock in your final configurations, you can also start production early. This means you run fewer lines for longer to fill your shipping channels. This can drastically relieve strain on your supply chain by reducing the number of tools and lines you need to qualify simultaneously.

But if you do need to hit a high volume for a tight launch window, ensure you have built in enough time to validate all the fixtures and equipment, train the operators, and qualify each process step. Engineers spend so much time making just one line work that it is inevitable that new lines will introduce new problems that may not have arisen in development. Qualifying production lines and production parts should be done by reducing as many variables as possible. For example, when bringing up a new line, qualify the tests and processes by using the same components and parts as on the original line. You can even assign the same operators to the new line to make sure they are able to replicate the performance of any previously qualified lines.

When bringing up new lines, you can use Instrumental’s test stations as critical pass/fail checkpoints on each line. Not only can you compare the output of each line with one another, but you can leverage the AI system to look for anomalies and make corrections across all lines or specific to any particular one that is out of spec. This should help you bring up the lines more quickly while reducing the number of devices to quarantine or scrap.

A recent example of a company failing quality checks as they tried to bring up a new line was Johnson and Johnson. Their manufacturer tried to get ahead by making test batches of their vaccine. Instead, the vendor made a critical mistake and ended up wasting 15 million desperately needed doses.

3. Keep up the quality

As you scale up production to meet the launch schedule, you also need to keep an eye on your incoming part quality. Some upstream vendors will promise you the world when you request initial quotes, but will fail to deliver at production when you need it most. Others run into problems that only come from scaling. To combat this, make sure your vendors have a plan to ramp production to the volumes you need. From qualifying copy tools and building out subassembly lines, they should be able to prove to you that they can build out their production capacity while maintaining quality control.

If you implement Instrumental stations throughout critical points in your supply chain, you can rest assured that the parts that they create and run through the stations will be the same ones that arrive at your factory. This means that everyone is on the same page and the parts will have met existing quality standards.

During the Kindle 2 production ramp, we had a surprising quality problem with our packaging vendor. During the prototype builds we had received great samples, but as we required larger quantities from them, the vendor was not able to produce. Our beautiful pulp packaging was coming in still damp and had holes in some corners. Instead of scaling up and getting our product out, we had to slow down and implement a screening process for quality control while simultaneously investigating the root cause. This meant training inspectors at IQC and on the line to look at our packaging and reducing our initial quantities to fill the channels adding unexpected costs to our manufacturing transformation and taking longer to earn it back with sales.

4. Implement an ongoing reliability plan

Additionally, make sure to implement a process of ongoing reliability testing to periodically sample devices from your production lines. Devices should pass a subset of the most critical reliability tests that were challenges for your design. Watch for any sign of declining performance as it might be an indicator of your process falling out of control.

If you have a manufacturing optimization system like the one from Instrumental, you can quickly go back and correlate data from the production line for devices you test in ongoing reliability. This saves time to FA the suspect devices because you can quickly get all the relevant information in real-time without having to guess what the state of the device was during manufacturing. If you also integrate your upstream vendors, you can get a complete picture of the product and confidently eliminate uncertainty about where the problems may lie and speed up your ramp.

5. Ship it early

As the economy recovers in fits and starts, transportation has become a surprising and vexing challenge for consumer brands. The stronger demand for goods combined with COVID restrictions has driven up shipping costs across the board.

Cargo ships are parked for longer at major ports as fewer dock workers came back to work or had to work under stricter health protocols. This has increased the lead times for processing cargo and for returning the containers to the manufacturing centers. The Suez Canal incident also slowed down global shipping for several weeks even after the Evergiven was unstuck because all those ships needed to get unloaded at the same docks.

Even when the goods are safely in-region, freight costs have increased. Increased fuel prices and a truck driver shortage make it harder to find capacity to get your products to the warehouse and ultimately their final destination.

Air freight, always a more expensive proposition, is also suffering from the increased fuel costs and reduced capacity. A significant portion of air freight capacity has been occupied by vaccines being transported around the globe while reduced volume of commercial jets has constrained supply. It takes some time for planes to get back into flying condition once they have been parked in the desert.

If you aren’t already doing so, it would be prudent to budget both additional time and money for the transit of goods. To load your channel, you may want to invest in a few strategic air freight deliveries for those earliest adopters while you wait for the sea shipments.

Bonus: Don’t let up now

If you are starting to ramp your product now, congratulations! In a year filled with uncertainty and multiple challenges, you managed to build something that consumers want and need. Now, more than ever, it is important to keep your guard up. Manufacturing is dependent on a lot of little things going right and can be easily derailed by any one thing out of place. By doing your part to guarantee your supply chain and manage your manufacturing processes you can minimize the risk to outside influences. Instrumental is helping its customers in NPI and through mass production by providing a connected platform that reduce barriers to information exchange that help identify and solve problems faster. If you want to learn more about how Instrumental can speed up your development and improve your ramp and production, contact us at sales@instrumental.com.

Related Topics