It’s lazy to think that a manufacturing process is better just because it’s automated. While the effort going on right now at the Tesla factory in Fremont is anything but lazy, it brings into the spotlight one of the core problems with the simplistic “automation for automation’s sake” strategy: processes that aren’t stable to begin with cannot be made stable with robots.

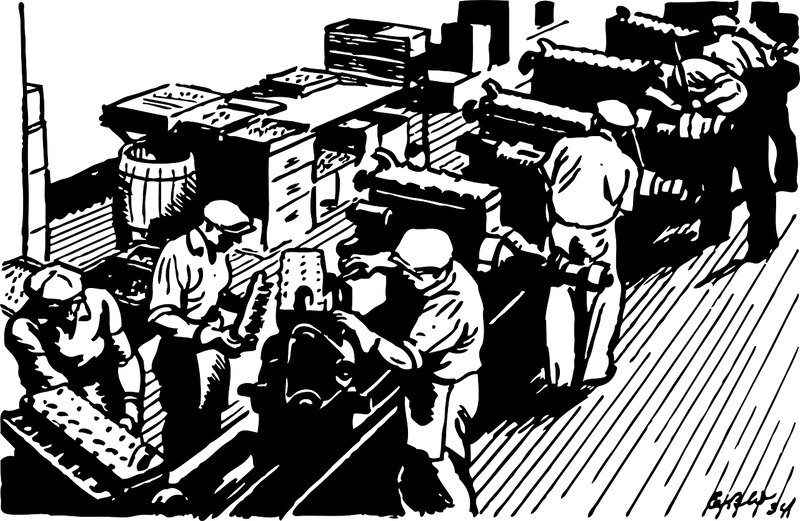

It might seem a bit counter-intuitive: humans are notoriously unreliable at performing a bunch of repetitive manufacturing tasks. Human visual inspectors regularly miss 20% of defects, but this number can go up significantly when humans are poorly trained, tired, or frankly, just don’t feel like doing their job well on any given day. Wouldn’t a machine that is following a program be an upgrade, every time?

Usually not. Even today’s most advanced assembly line robots can be flexible in some ways, but are not yet infinitely flexible like humans are. Interestingly, consistency and quality are almost never the reason manufacturers look to robots; it’s usually about reducing costs. There are certainly exceptions, such as with semiconductor or chip fabrication, where it’s not possible to make the parts “by hand” and automation from day one is the only option (one that causes the length of development schedules to explode). Ultimately, desire to reduce human headcount is the main driver of automation, and depending on the industry, factories expect to make their money back over 18–48 months through a combination of savings on wages and increased throughput since fully automated lines can often produce parts faster.

Does that mean that Tesla’s quest to automate an entire factory as a key competitive advantage is a fool’s errand? Not at all, it’s brilliant. It’s easy to see the logic that it might be easier to design a product to be fully automated from day one. It’s true: you need to design the product with automated assembly in mind in order to ever get there. But the mistake is in thinking that once you’ve built one unit – whether it’s a car or a cell phone – that building millions just means dumping a lot of robots on the line. In actuality, product design is a messy process. I was a product design engineer at Apple for nearly six years, and since then have seen the inside of many processes as CEO of Instrumental. In the consumer electronics industry, it takes multiple iterations of the entire product before it’s even possible to consistently build it with human hands. All during that phase, geometric and other changes are being made, sometimes many times each day. Human operators are really flexible and can quickly adjust to these changes – usually a quick conversation about what changed and how their task needs to change is enough. Robots are rigid – that “quick conversation” is now a multi-hour reprogramming session, often with an expensive consultant. Nothing kills productivity on a development line like automated equipment. I’ve seen this first hand. I’ve also seen that very same automated equipment be top on the list to get ripped out in the next generation of the product (by the engineers who had to deal with it, anyway). Even though Model 3 is in “production”, it’s clear from Elon Musk that the iteration phase is still very much underway. As Elon said, “humans are underrated”.

Nothing kills productivity on a development line like automated equipment.

While one team of engineers is working on making sure the design is good, there’s often another team working to make sure that the part quality and process is stable. Humans can adjust to variation, but robots usually cannot. If the incoming parts are bent a little differently because they come from a different supplier or if the holes are a little off (think about the last time you put together Ikea furniture), a human operator can accommodate their process enough to make it work. To be ready for automation, all of that variation needs to be tuned out, requiring a systematic approach that today remains very human-centric (though there is hope that machines will be able to do this in the future). While advanced technology like Instrumental’s can be used to spot variations, highlight them, and even support the failure analysis process, engineers today are still needed to take computer-supported insights, find a root cause, and then eventually determine the corrective action. On a human assembly line, these process engineers can work on many variation problems in parallel because the line is still running and producing samples at each point in the process for them to study and experiment on. On a robotic line, the first major variation brings down the first machine, and no parts get through at all, requiring that each problem be solved in series. It’s much slower, way more expensive, and incredibly frustrating.

Responsible automation is a multi-step process. The upfront investment in designing a product that can be assembled in an automated way is a nontrivial part of success, and one that has to happen long before robots get their little end effectors on parts. Next comes the rapid iteration phase of new product development, where prototypes of the product are assembled on an assembly line by humans. The flexibility of that line enables many changes to be made in a short period of time, accelerating the development process.

While development processes look different in different industries, it’s usually a period of six to eighteen months where a few iterations of the products are built. During the later stages of development, some steps of the assembly process may become stable, and the initial human assembly line may be hybridized with simple or commonly used robots. For example, in automobile manufacturing, the body shop phase of assembly has been done with robots for a long time, so it makes sense to bring those up early on and pocket the efficiency gain, even if humans continue to do other parts of the process. Regardless of industry, the first line that is qualified to make units for customers will likely still have human assembly operators. Line qualification is a big milestone, and most companies will launch the product and start shipping at that point. They may choose to build more hybrid lines to ramp up capacity first in order to hit numbers, and then once some of the pressure is off, work on automating new lines as a cost-reduction and efficiency improvement process. The advantage of this process is that figuring out automation isn’t gating products from streaming off of lines to hit production numbers, and those products and lines can serve as a “golden reference” for product quality that must be met in order for any new line or automated process to be qualified to ship to customers.

For an industry like automotive where the changes from the 2017 to 2018 model are usually not significant and the same model can run for decades, the capital and development costs of automation are a no-brainer investment. Each model year often only has minor cosmetic design changes, giving engineers the opportunity to work on automating key parts of the process from generation to generation. Tesla Model 3 is just not there yet. Many companies in automotive or other manufacturing verticals who are considering automation for its cost reduction benefits aren’t there yet either. They view automation as “step one” in a cost-reduction plan, prioritizing it even in development before finding and fixing problems. In actuality, finding and fixing problems needs to be “step one” in order to create a process that is stable enough that automation can be a strong “step two”. As we’ve seen with the Tesla example, trying to skip ahead can end up costing way more money and time.

A version of this post was originally published on Forbes.com.

If you agree that finding and fixing issues should be “step one” in your cost-reduction plan, we’d love to learn more about the challenges you are facing and how we can help. Drop us a line.

Related Topics