Download the definitive guide to manufacturing optimization

Learn the history of manufacturing optimization, basic and advanced optimization techniques, and see real examples of manufacturing optimization in action.

Get 70+ pages of manufacturing optimization best practices for high-volume and mission-critical electronics brands.

Learn the history of manufacturing optimization, basic and advanced optimization techniques, and see real examples of manufacturing optimization in action.

Executive Summary on Manufacturing Optimization

Ask yourself: How many of your programs have suffered delays because it took too long to find and fix an issue propagating through your line?

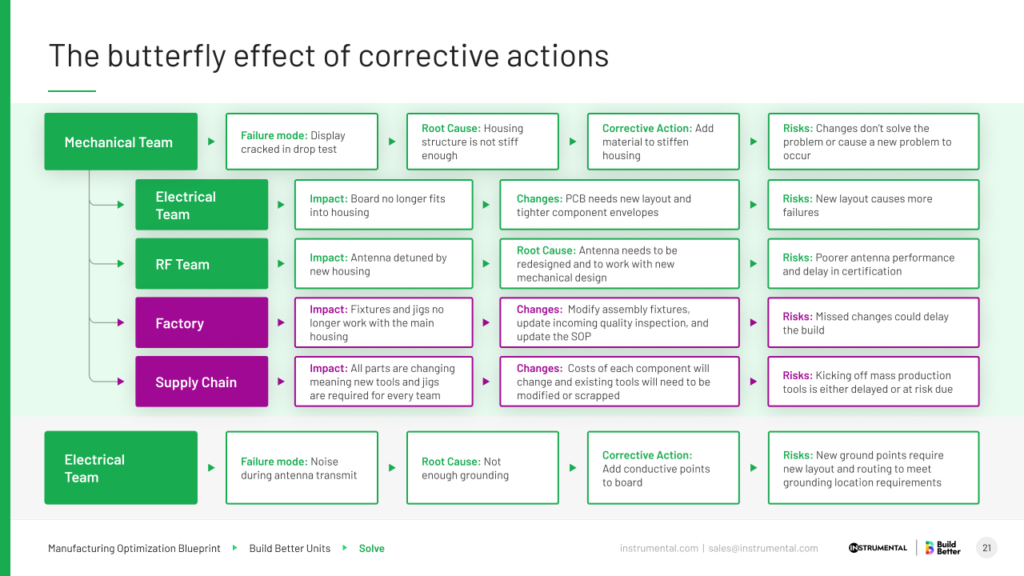

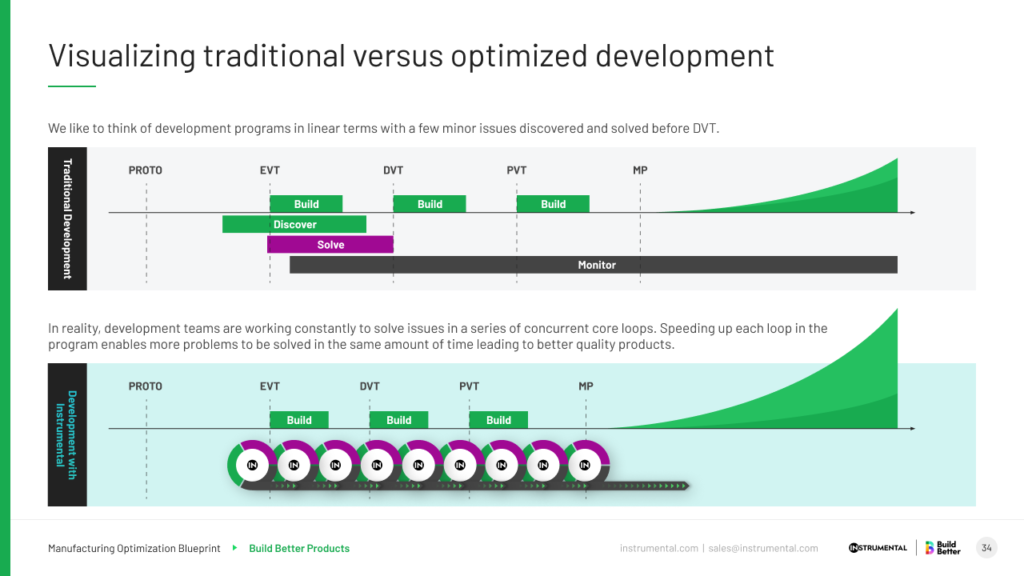

It’s a common problem in electronics manufacturing. Though the challenges facing any individual build are unique, the central problem facing product design engineering teams is how to quickly and repeatably find and fix issues to keep builds on schedule.

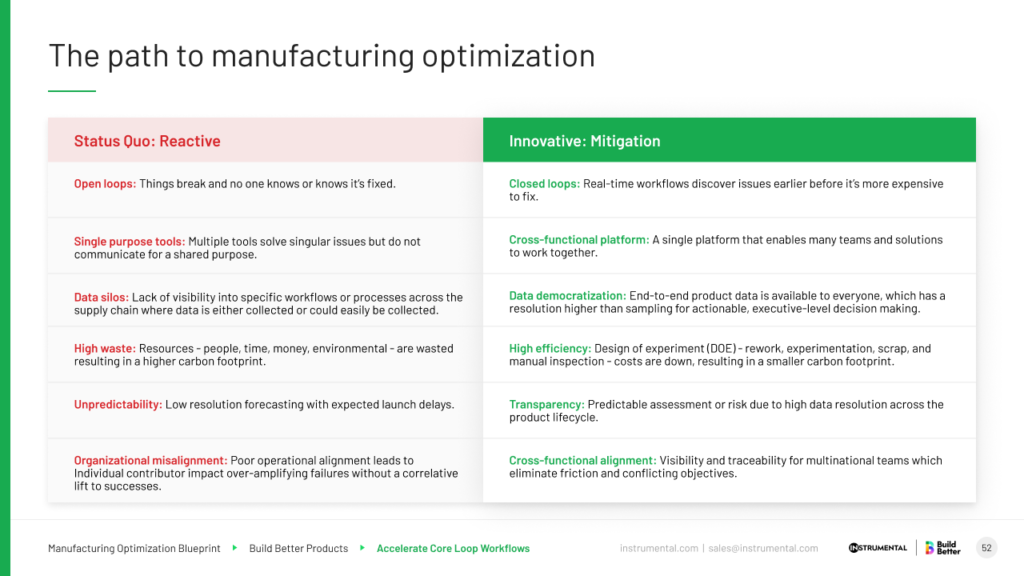

And it’s leading to billions of dollars in waste. But why is the problem getting worse, and not better? Why haven’t we optimized the process around issue discovery and solution validation across the supply chain? Because manufacturing continues to be stubbornly analog and engineers prefer to be heroes on the factory floor.

Prior to the global pandemic, electronics manufacturers could get away with relying on traveling engineers conducting complex forensics on the line. Only a decade ago, the schedules were longer, the teams were smaller, and the products were simpler. It was far easier to solve different problems at the unit-level to hit a ship date and ignore population-level optimization exercises. Now, the schedules are more aggressive, the products are more complex, the teams are larger, and travel to factories is harder. Solving problems only a few units at a time on the factory floor isn’t going to cut it anymore.

In order to recover the billions of dollars in waste, electronics manufacturers will have to think bigger than solving problems one unit at a time in mass production. This means they’ll need to reimagine what forensics and optimization truly mean—and when it happens. Modern manufacturing optimization is about scale and speed—and that takes new tools and technology. We’re here to show you what that means.

Check out a few pages of our handbook below:

While 53% of 2020 programs were canceled, 100% of Instrumental customers shipped. We attribute this resiliency not to Instrumental, but to a commitment to a culture of continuous optimization across the supply chain. Learn how you can create a culture of optimization with Instrumental today.

Learn more