-

ProductBack

Product

-

ResourcesBack

A place for visionaries to learn from their peers about getting culture right, NPI, Production, and evaluating new technologies

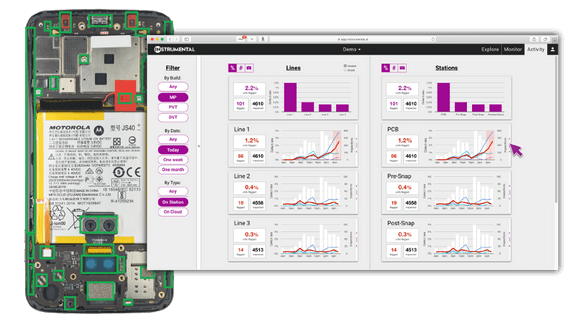

See how companies are using Instrumental

-

CompanyBack

- Log in SPEAK TO AN EXPERT

- Search