The Manufacturing Operations Dashboard Revolution

Picture this: You’re an operations leader in the electronics manufacturing industry, and you’re constantly striving to hit yield targets while managing the complexities of production. You’re expected to provide quick answers to your organization’s most pressing questions, but the data you need is scattered across multiple sources and stakeholders. Sound familiar? Enter Instrumental’s Manufacturing Operations Dashboard – your all-in-one solution for real-time oversight, manufacturing root cause analysis, and live SPC alerts.

Meet Santiago, Your Operations Manager’s Alter-Ego

Santiago, an operations manager, used to spend countless hours gathering key performance metrics for his monthly leadership meetings. Now, with Instrumental’s Manufacturing Operations Dashboard, he receives live alerts on manufacturing yield targets and can easily pinpoint issues when they arise. Armed with the right tools, Santiago enters the meeting with confidence and takes control of his program’s manufacturing performance.

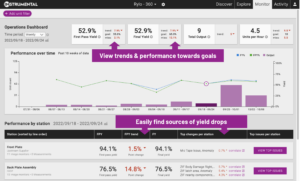

Discover the Power of Real-Time Oversight

Instrumental’s Manufacturing Operations Dashboard offers actionable, real-time insight into factory performance through data visualization. By continuously monitoring test results, identifying trends, and providing personalized manufacturing SPC alerts, the dashboard empowers your team to take corrective action before yield and output are impacted. Santiago said goodbye to endless data-hunting and embraced the power of real-time oversight: he keeps a careful eye on more programs than he’s ever been able to before.

Live Alerts to Keep You on Track

Stay ahead of the game with live alerts – not just for manufacturing yield targets, but also proactive alerts on unexpected SPC violations that could soon impact yield. Instrumental’s Manufacturing Operations Dashboard keeps you informed and ready to act. When Santiago gets an alert one morning indicating a sudden drift in the performance of the antenna test station that could soon start to impact his First Pass Yield (FPY), he uses the Manufacturing Operations Dashboard to immediately pinpoint the Bluetooth antenna transmission power test as the culprit. The dashboard provides a place to prioritize and start any continuous improvement mission.

Quickly Find and Fix Issues with Manufacturing Root Cause Analysis

The Manufacturing Operations Dashboard takes the guesswork out of finding and fixing issues when they arise. From the dashboard, Santiago can click directly into the Bluetooth transmission power test and leverage Instrumental’s powerful AI Correlations tool to rapidly identify relationships between test failures and other factors – like the test station’s firmware version, in Santiago’s case. Instrumental enables the kaizen philosophy, reducing time spent on manual root cause analysis and spending more time taking action. Santiago gets on the phone with his test engineer at the factory to quickly hash out a corrective action, preventing a yield hit and getting the program back on track.

Benefits Beyond Real-Time Oversight

The Manufacturing Operations Dashboard goes beyond real-time oversight, offering a suite of benefits to elevate your lean manufacturing operations:

- Set and track performance against goals – keep an eye on your yield and throughput objectives, identifying areas where improvement is needed.

- Prioritize team focus – use advanced analytics to pinpoint high-impact improvement opportunities, directing your team’s efforts where they matter most.

- De-risk production line changes – assess the impact of changes in real-time, enabling quick optimization of processes.

- Collaborate with global teams – break down barriers and work together to tackle challenges, regardless of location.

Ready to Supercharge Your Manufacturing Operations?

If you’re eager to take things to the next level, reach out to us at Instrumental today. Discover how our Manufacturing Operations Dashboard can help you achieve real-time oversight, live alerts, and efficient root cause analysis – all while keeping you ahead of the competition.

Learn more about how to modernize your manufacturing process here.

Instrumental Surpasses Three Billion Manufacturing Data Points Processed

Related Topics