As a product designer, one of the biggest compliments you can get is when the end-user has no idea how the product was put together. An even bigger compliment is when fellow designers can’t figure it out either. More and more products these days have few or no visible fasteners making it seem like they were put together by magic. That magical experience is often the result of countless hours of clever engineering and development work starting from the earliest architectural design decisions like choosing between screws and glue.

In recent years, many engineers have turned to glues and tapes to make their products sleeker. These adhesives are thin and versatile helping disguise how a product was made but also making it smaller, more durable, and waterproof. Using adhesives is often justified by the increased durability of the products which translates to fewer product returns and repairs.

However, critical components like the battery and display often fail within 1-2 years of heavy use incentivizing users to buy the latest product and throw out the old devices. To combat this growing problem of e-waste, the European Union has passed laws codifying the right to repair. This means engineers will need to dig deep again to figure out how to strike the right balance between form, function, reliability, and repairability.

In this article, we will explore some of the pros and cons of using screws and glue to assemble products and what we might be able to expect as the new laws are implemented in Europe.

Designing with Screws and Glue

Screws offer designers a straightforward method of assembling parts together. The way they translate rotational torque to axial force allows them to sandwich components between the screw and the mating nut or tapped hole. This is useful for clamping parts against a design datum and resisting oppositional forces from spring contacts, buttons, or foams. Often charging connectors are screwed in place to help withstand the loads from repeated insertions that might otherwise weaken nearby solder joints.

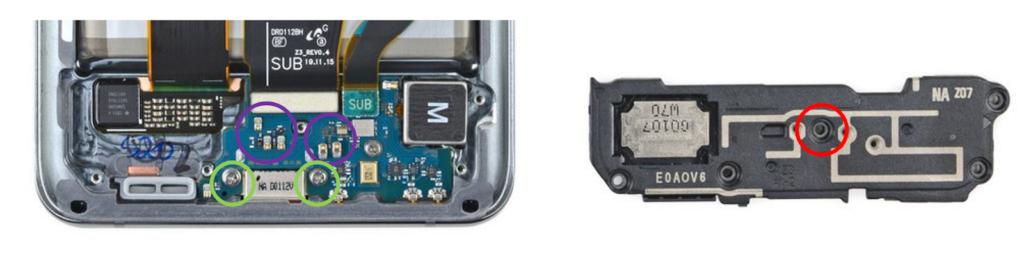

Photo Credit: Fixit Galaxy S20 Ultra teardown. The purple circles indicate spring contacts to the speaker, the red circle indicates a screw through hole to engage the contacts. The green circles indicate screws on either side of the charging connector.

Because screws are usually made from a plated steel or other metal, they often serve dual purposes with printed circuit boards. Not only are they used to fasten the PCB to the housing, but they can also provide electrical ground connections helping to reduce interference with the ever-increasing number of antennas in consumer products.

While screws can be easily customized to fit your desired length, diameter, pitch and drive type sometimes there is not enough space in the X, Y, or Z axis to accommodate the screw head or the mating screw boss. For example, an edge-to-edge display module with 2mm perimeter bezels, does not have enough space to hold a screw boss for some of the smallest screws in use today. Instead, most display modules and coverlenses make use of liquid glues and adhesive tapes to bond them to the housing.

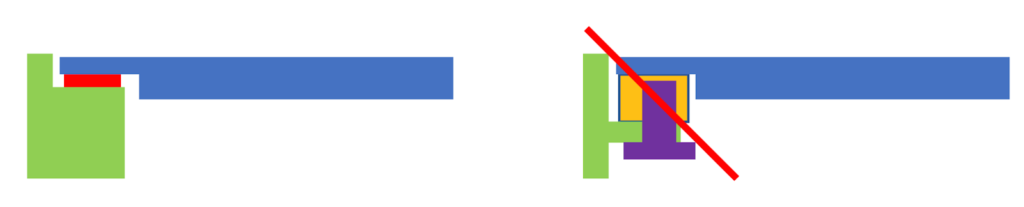

An example cross-section through an edge-to-edge display. The image on the left shows the narrow bonding area for the red adhesive strip while the image on the right shows that there is not enough available room to attach a screw boss to the cover lens without it interfering with the display.

Adhesives are often used in areas where there is limited space and complex geometries. These materials take advantage of the adhesive properties distributed over a larger surface area to create a strong bond. Even in a narrow opening, liquid glue can be dispensed as a continuous bead and tapes can be die-cut as solid rings. This makes both types of adhesive ideal choices for preventing water or dust ingress into an assembly. Liquid glues or foam-backed adhesives are more compressible than screws and can accommodate greater tolerance variation in the mating parts. While liquid glues might cure or harden over time, they can flow and take up the gap when initially manufactured.

Battery cells in a consumer device are often some of the largest and thickest components. This means it is easier to use thin sheets of adhesive to affix the battery in place than add additional material for a frame and find room for screw bosses. Using adhesive instead of other fastening methods also reduces the risk of puncture from an errant screw.

Screws and Glue on the Assembly Line

At the assembly line, screws are generally easy to manage. They store well in moderately controlled warehouses and don’t go bad unless exposed to extremely corrosive conditions. If there are multiple types of screws to track, it becomes a bit more challenging to manage inventory and line stations. Processes need to be put in place to ensure there is no cross-contamination between different screws. To combat this, some brands like to use different drive types, plating colors, or sizes for different applications to clearly identify when the wrong screw is used.

Screws do have some process requirements for use on the line. This includes specifying and calibrating the torque of the drivers and having protocols to deal with the rare situations of bare or broken heads and stripped threads on the mating component. If there are a lot of screws in an assembly it is quite easy for an operator to miss one or more of them so having an automated system to check that screws are in place is quite useful.

Adhesives on the other hand tend to have a lot more challenges in processing and storage at the factory. They are more sensitive to environmental conditions like temperature and humidity which can affect the chemical composition of the bonding agents. Adhesive tapes can be bent or folded easily which could cause the adhesive to bond with itself or become exposed to the air and particles.

Despite serving a similar purpose, there is a difference between liquid glues and adhesive tapes in how they are used on the line. Liquid glues like two-part epoxies or optically clear adhesives often require special dispensing machines and time to set under compression. These dispensing machines themselves need to be programmed and tested to be repeatable. Liquid is also less predictable because it can flow differently depending on the age of the material, the ambient conditions, and even how long it has been in the dispenser. While your design may call for a continuous bead of glue in your assembly, small variations in your process or materials can cause issues like gaps, too much glue or too little.

Adhesive tapes are often pressure-sensitive which means they require force to fully activate. To ensure consistency in manufacturing, special fixtures are often needed to both assemble and apply the necessary pressure and time. Adhesives are difficult to place without alignment fixtures. Sometimes vacuum fixtures are used to hold the liners in place. Once applied, adhesives are difficult to rework or remove especially if they are designed to be aggressive. This means scrap and rework costs increase if there is a problem with an assembly.

In a recent survey of our Instrumental customer data, 4 of the top 10 problems in production related to the usage of glue, or adhesive-backed tapes, foams, and labels. Too much glue can cause cosmetic problems or fit issues as adhesive flows into areas it is not supposed to be. Too little glue and the required strength or sealing may not be achieved. Adhesive-backed materials like tapes and foams can also cause problems if not installed properly. Wrinkles in adhesive mean reduced surface area for bonding and potential tolerance problems as the adhesive takes up more space than designed for. Find out more details about these defects by downloading Instrumental’s Top 10 Defect Types in Production report here.

Repair and Recycling with Screws and Glue

Once a product leaves the factory, it will be subjected to the wear and tear of the real world. Parts break and wear out or a new generation is released leaving customers with the option to repair or recycle their old devices.

Repairing devices with a lot of screws is generally much easier than those that are glued shut since screws are designed to be reusable. Even with screws, repair can be a little tricky. Some devices use special security screws requiring customized drivers. By now, everyone knows that iPhones use pentalobe screws on the outside and sometimes tri-wing screws on the inside. Often devices use more than one type of screw. If the consumer is not careful, they could inadvertently use the wrong screw when repairing or reassembling their devices. A long screw in the wrong place could puncture through a sensitive component like the display or battery. With small screws, the wrong torque could cause the screws to back out or break the head off. Recently, Amazon’s Ring Doorbell faced a recall when customers mistakenly used long mounting screw in the wrong place damaging the rechargeable battery potentially starting fires.

Devices like phones and smart watches will likely continue to use adhesives as a physical barrier for waterproofing and other durability reasons. However, the European push for the right to repair will encourage brands to innovate and find ways to make it easier for consumers to repair devices themselves.

While many devices do use adhesive around the perimeter, that adhesive may not need to be quite as aggressive if the key modules are all waterproof. Companies like Instrumental customer P2I deposit a nanocoating over the entire surface of the board protecting all exposed leads and solder joints from shorting when exposed to water.

We are also starting to see an increased adoption of weak-shear adhesives underneath batteries. These adhesives are similar to those popularized by the 3M Command Strips which are quite strong in the perpendicular directions, but weak in the parallel direction. This allows the adhesive to be pulled off at a low angle leaving little residue behind. Sometimes, aging can sometimes cause the pull tabs to break earlier than expected, but this is an exceptional example of companies adopting new technologies to improve repairs.

As the right to repair movement gains momentum, questions will arise on who bears responsibility for repaired products that fail. Brands spend a lot of time and effort to make their products meet high standards for consistency and reliability. But once a 3rd party opens up the device, manufacturer warranties are often voided.

Making the right choice

Regardless of whether the new European regulations cause you to rethink how you put your products together, Instrumental can help you find and fix problems that distract you from implementing the right fastener.

By identifying issues in NPI as they happen instead of waiting for problems to be discovered during reliability testing, Instrumental has helped teams reduce wasted effort and materials in development and into production. Earlier discovery of anomalies in glues, adhesives, and screws means the engineering team can dial in process parameters and adapt on the fly instead of waiting for test results weeks later.

For glues, this can be especially helpful because the team can screen common issues and track progress across builds and into production. This allows the team to focus on continuously improving their designs and processes during the build instead of waiting for reliability results to make crucial decisions.

For screws, checking not only for the presence of them, but also the condition of the head and driving recess can catch operator errors and process parameter problems before the product gets fully assembled, tested, and shipped out.

In production, this ability to detect and monitor in real-time translates to higher yields and fewer repairs when issues with adhesive and screws are discovered before expensive components are attached to one another. Instead of costly repairs or customer escapes, many of these units can be reworked and recovered.As consumers and governing bodies become more aware of the entire lifecycle of a product and demand the ability to repair products, our job as designers and builders will be to strike the right balance between how the product performs in use and how to enable them to make repairs after the fact. Using new tools like Instrumental can make those decisions faster and easier. To find out how Instrumental can help you with your product’s glues and screws, contact us at sales@instrumental.com.

Related Topics