Product

A place for visionaries to learn from their peers about getting culture right, NPI, Production, and evaluating new technologies

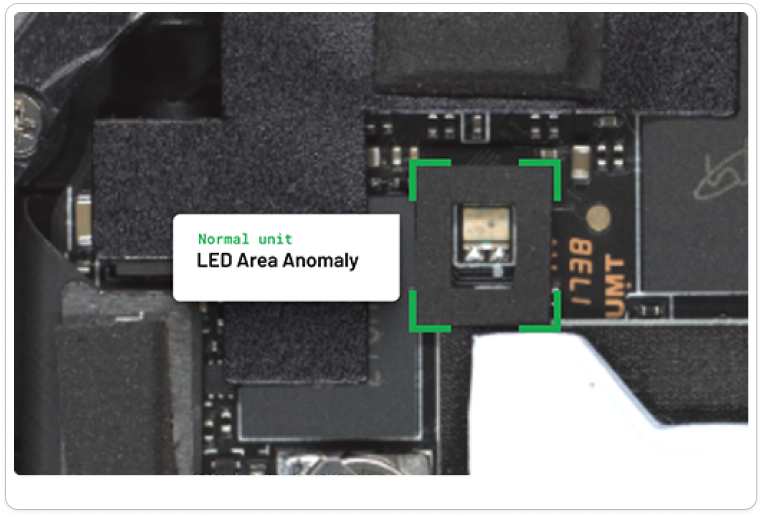

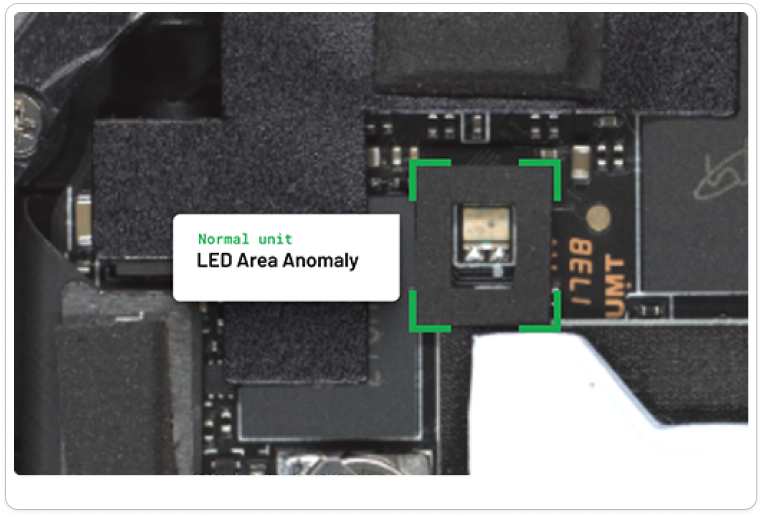

See how companies are using Instrumental

Instrumental has saved us time and money by quickly identifying issues. This allows us to catch problems early and avoid costly teardowns and rework.

Oded Rivel

Project Management Team Lead, SolarEdge

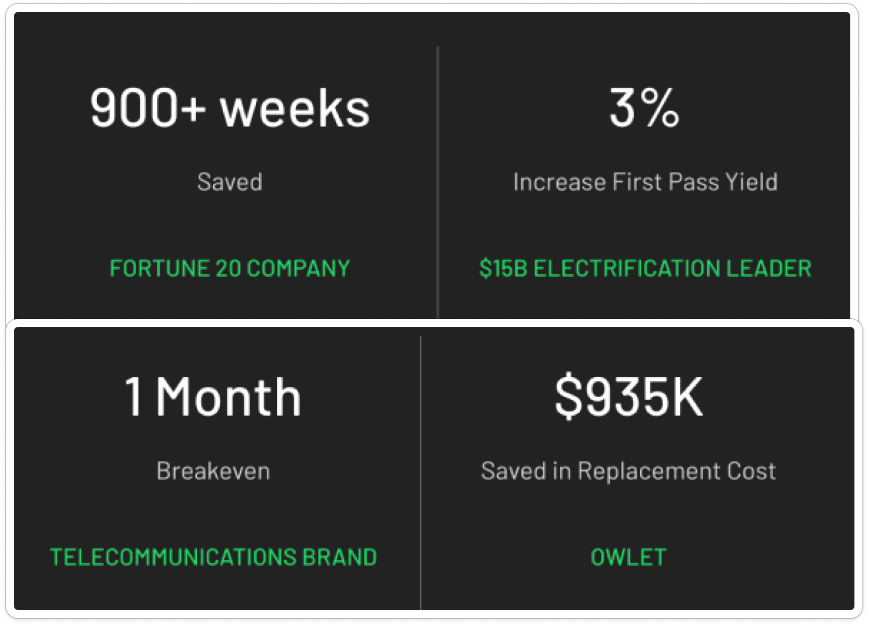

Instrumental saved us 900+ engineering weeks, a core metric for Meta, unlocking capacity across our hardware and software teams.”

Steve McClure

Senior Director of Hardware Engineering, Reality Labs

By using Instrumental, it was like being at the factories. The transparency Instrumental provided resulted in more prompt attention and a higher level of care for our line, putting us on the same level of priority as other customers with higher volume.”

bill maginn

Operations Engineering and NPI leader, Axon

Programs that used Instrumental during development ramped faster than products that did not use it.”

Director of Engineering and NPI

Motorola Mobility

Without Instrumental, fixing the issue and delivering customer satisfaction would have been slower, harder, and more expensive.”

Burc Sahinoglu

Chief Technology Officer

Nobody provides the contextualization and user experience that Instrumental has developed. This is the holy grail of data correlation. ”

Mike

Director of Operations, L3 Harris

Instrumental helped us quickly identify major impacts to our units and gave us data to back up what to do next.”

CHRIS FISHER

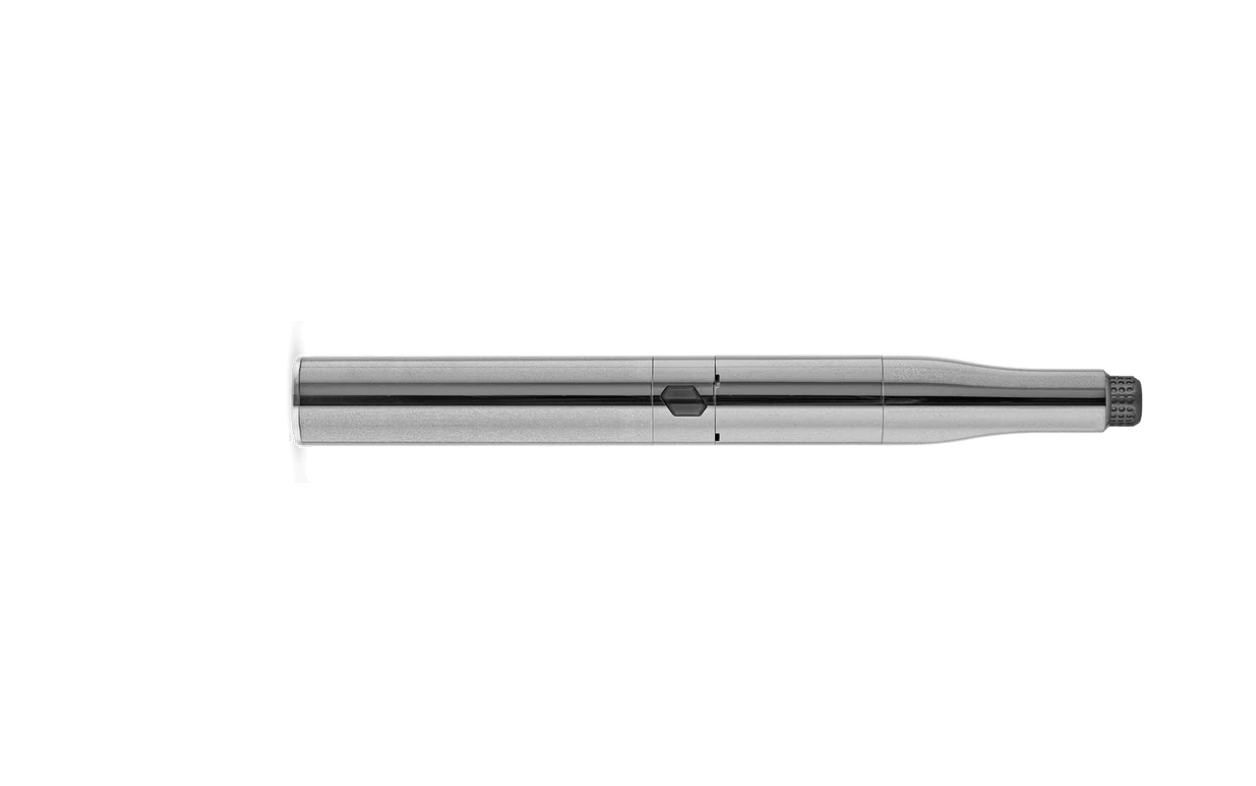

Senior Test and Quality Manager, PuffCo