-

NPI: A How To Guide for Engineers & Their Leaders

-

Leading from the Front

-

Building the Team

-

Screws & Glue: Getting Stuff Done

-

Choosing the best CAD software for product design

-

Screws vs Glues in Design, Assembly, & Repair

-

Best Practices for Glue in Electronics

-

A Practical Guide to Magnets

-

Inspection 101: Measurements

-

OK2Fly Checklists

-

Developing Your Reliability Test Suite

-

Guide to DOEs (Design of Experiments)

-

Ten Chinese phrases for your next build

-

-

NPI Processes & Workflows

-

-

Production: A Primer for Operations, Quality, & Their Leaders

-

Behind the Pins: How We Built a Smarter Way to Inspect Connectors

-

Former Apple Executive Bryan Roos on Leading Teams in China and Managing Up

-

Responding to Rare-Earth Supply Chain Risks: A Quick Guide for Manufacturers

-

Logitech’s Approach to Collaboration with Manufacturing Data

-

Leading for Scale

-

Navigating Factory Moves and Scaling Production in an Era of Uncertainty with PRG's Wayne Miller

-

Steven Nickel on How Google Designs for Repair

-

Petcube’s Alex Neskin Embraces Imperfection to Deliver Innovation

-

Proven Strategies for Collaborating with Contract Manufacturers

-

Greg Reichow’s Manufacturing Process Performance Quadrants

-

8D Problem Solving: Sam Bowen Describes the Power of Stopping

-

Cut Costs by Getting Your Engineers in the Field

-

Garrett Bastable on Building Your Own Factory

-

Oracle Supply Chain Leader Mitigates Risk with Better Relationships

-

Brendan Green on Working with Manufacturers

-

Surviving Disaster: A Lesson in Quality from Marcy Alstott

-

-

Ship It!

-

Production Processes & Workflows

-

-

Thinking Ahead: How to Evaluate New Technologies

-

How to Buy Software (for Hardware Leaders who Usually Don’t)

-

Adopting AI in the Aerospace and Defense Electronics Space

-

Build vs Buy: A Guide to Implementing Smart Manufacturing Technology

-

Leonel Leal on How Engineers Should Frame a Business Case for Innovation

-

Saw through the Buzzwordspopular

-

Managed Cloud vs Self-Hosted Cloud vs On-Premises for Manufacturing Data

-

AOI, Smart AOI, & Beyond: Keyence vs Cognex vs Instrumentalpopular

-

Visual Inspection AI: AWS Lookout, Landing AI, & Instrumental

-

Manual Inspection vs. AI Inspection with Instrumentalpopular

-

Electronics Assembly Automation Tipping Points

-

CTO of ASUS: Systems Integrators for Manufacturing Automation Don't Scale

-

-

ROI-Driven Business Cases & Realized Value

-

-

Webinars and Live Event Recordings

-

Overcoming the Three-Body Problem in Electronics Manufacturing

-

The Frontier of Trust - Build Better 2025

-

Outsourced: Industry Perils of Delegating Too Much of Product Innovation and Ownership | Build Better 2025

-

The Frontier of Electronics Complexity: The Many Bottlenecks of AI Compute Infrastructure

-

Limitless Acceleration: The Frontier of Schedule Velocity in NPI and Production

-

The Apple-China Symbiosis and What it Means for the Future of Electronics with Patrick McGee

-

Get Me Outta Here! Racing to Full Production Somewhere Else

-

Tariff Talk for Electronics Brands: Policies Reactions, Reciprocal Tariffs, and more.

-

Materials Planning: The Hidden Challenges of Factory Transitions

-

Build Better 2024 Sessions On Demand

-

Superpowers for Engineers: Leveraging AI to Accelerate NPI | Build Better 2024

-

The Motorola Way, the Apple Way, and the Next Way | Build Better 2024

-

The Future of Functional Test: Fast, Scalable, Simple | Build Better 2024

-

Build Better 2024 Keynote | The Next Way

-

Principles for a Modern Manufacturing Technology Stack for Defense | Build Better 2024

-

What's Next for America's Critical Supply Chains | Build Better 2024

-

Innovating in Refurbishment, Repair, and Remanufacturing | Build Better 2024

-

Leading from the Front: The Missing Chapter for Hardware Executives | Build Better 2024

-

The Next Way for Reducing NPI Cycles | Build Better 2024

-

Scaling Manufacturing: How Zero-to-One Lessons Unlock New Opportunities in Existing Operations | Build Better 2024

-

-

Build Better Fireside Chats

-

Aerospace and Defense: Headwinds & Tailwinds for Electronics Manufacturing in 2025

-

From Counterfeits to Sanctions: Securing Your Supply Chain in an Era of Conflict

-

Design for Instrumental - Simple Design Ideas for Engineers to Get the Most from AI in NPI

-

Webinar | Shining Light on the Shadow Factory

-

Tactics in Failure Analysis : A fireside chat with Dr. Steven Murray

-

-

Preparing for Tariffs in 2025: Resources for Electronics Manufacturers

-

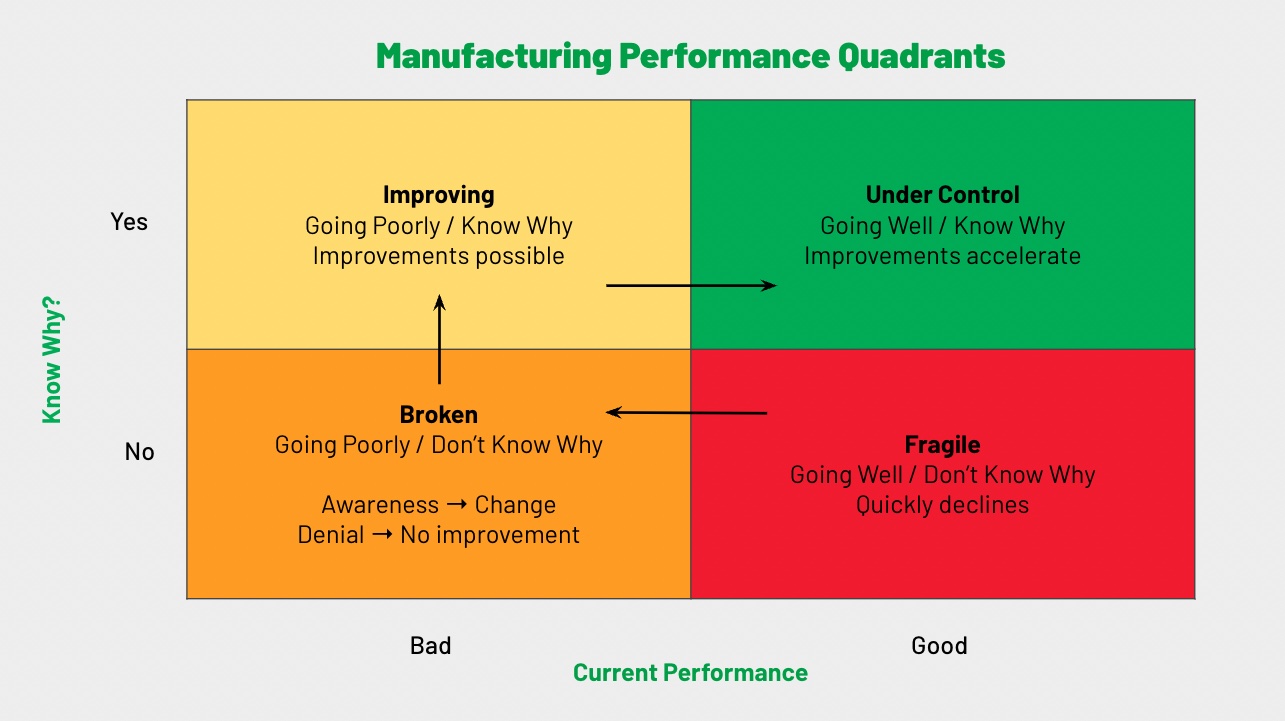

Greg Reichow doesn’t mince words when he talks about a major challenge in manufacturing: “I’ve been shocked at how poor problem-solving is in most places.” Now a General Partner at Eclipse Ventures, Greg was a vice president in operations and production at Tesla for over five years, following a successful career in various manufacturing and quality roles. He has witnessed good and bad examples of production floor problem-solving and is trying to fix it. Greg advocates for smart assessment of manufacturing process capability, including the team in that process. He helps teams and companies determine the health of their program using a simple framework: the Manufacturing Performance Quadrant.

Greg Reichow doesn’t mince words when he talks about a major challenge in manufacturing: “I’ve been shocked at how poor problem-solving is in most places.” Now a General Partner at Eclipse Ventures, Greg was a vice president in operations and production at Tesla for over five years, following a successful career in various manufacturing and quality roles. He has witnessed good and bad examples of production floor problem-solving and is trying to fix it. Greg advocates for smart assessment of manufacturing process capability, including the team in that process. He helps teams and companies determine the health of their program using a simple framework: the Manufacturing Performance Quadrant.

Using the Manufacturing Performance Quadrant to solve manufacturing problems

Greg believes this problem-solving quadrant applies to any vertical but is especially relevant in electronics manufacturing.

“In electronics manufacturing, you’re building small things that you can’t see with the naked eye,” Greg said. “Incredible precision is required to build billions of transistors on a single computer chip, which means two things: hundreds of things can go wrong, and teams end up looking the other way when things are going well.”

This philosophy is the foundation of a pervasive myth in manufacturing — that things are under control when things are going well. It doesn’t necessarily mean that. The Manufacturing Performance Quadrant explains why.

The Manufacturing Performance Quadrant

First, here is a brief review of each part of the quadrant.

Under Control: A state of success

This stage is in the upper right corner, in green. Teams with programs in this stage deliver quality products, meet yield targets and know exactly why the program is running smoothly. This is where continuous improvements can happen. The challenge is to get there and stay there.

Improving: A state of potential

This stage is in the upper left corner, in yellow. Programs in this stage are failing somehow — but the team knows why. Maybe a known design flaw is causing failures, or a component from an upstream supplier isn’t meeting quality standards. But in this stage, because teams know the problem, making improvements possible.

Broken: A state of disorder

This stage is in the lower left corner, in orange. Programs in this stage are broken because things aren’t going well, and teams don’t know why. This can lead to two possible outcomes: if teams admit things are broken, they can move to the “improving” stage because they know there’s a problem. If they’re in denial, however, improvement is no longer an option, which could lead to permanent failures down the road.

Fragile: A state of danger

This stage is in the lower right corner, in red. Programs in this stage are running smoothly — but teams don’t know why. It’s the most dangerous part of the quadrant because, on the surface, it looks “under control.” In reality, a lack of knowledge could cause a rapid and sudden decline into “broken.”

The risk of confirmation bias

Greg believes that understanding the status of your program within this framework is the first step to change. But there’s a hurdle that can prevent necessary action: confirmation bias. Confirmation bias causes team members to believe they’re in one quadrant when in reality, they’re in another.

At one point, Tesla was developing a new drive unit for the Model S to improve performance and range. They also wanted to make it quieter. So, the team decided to first focus on building a more efficient motor, with plans to address the noise issue later in the process.

“This happens a lot in engineering,” said Greg. “You focus on solving for one set of parameters, and you end up writing off problems already lurking, thinking, ‘I’m smart, I know that’s going on, and it won’t be an issue later.’ You don’t want to believe that it’s a problem.”

Unfortunately, while working in this “fragile” state, the noise problem they hadn’t addressed became a big concern. After more than a year of development, and on the eve of the launch, Elon Musk took the car for a test drive and, in Greg’s words, was “disgusted” at the noise coming from the drive unit. The Tesla team later found the solution with better mounts and insulation — but it required expensive repairs and delayed the release.

“It goes to show that it’s important to have the unvarnished truth about how things are performing as early as possible,” said Greg.

Applying the Manufacturing Performance Quadrant to Leadership

Just as manufacturing teams can use the Manufacturing Performance Quadrant to measure the health of their programs, leaders can use it to assess the health of their teams and build a team culture.

“If you’re in a meeting and someone is describing a really ugly problem, your first reaction won’t be filled with anxiety or dread. It will be, ‘Great! This person has found a problem, now we can fix it!’” Greg said. “The quadrant can help leaders see that identifying problems is really identifying opportunity.”